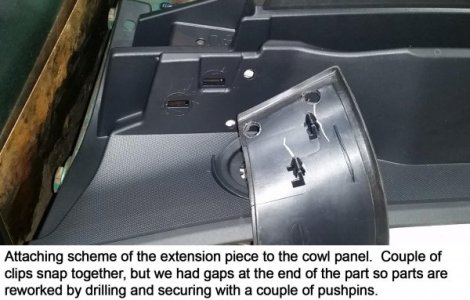

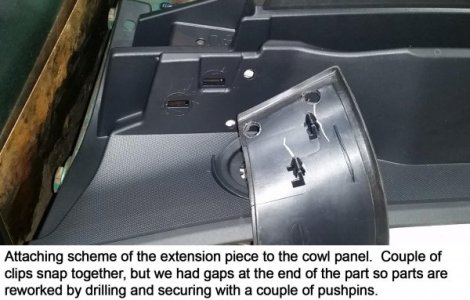

POTD was a “government job” for work. I’m a quality engineer at the Lansing Delta Township Assembly Plant where we make Chevrolet Traverse and Buick Enclave models. We had a fit concern on the Buick where the cowl extension and cowl could gap to each other. The concern was contained with a piece of aggressive 2-sided tape. However, the tape was a pain for the folks on the floor as it stuck to their gloves when peeling off the backer, so went with an alternative containment with a couple of push pins into drilled holes.

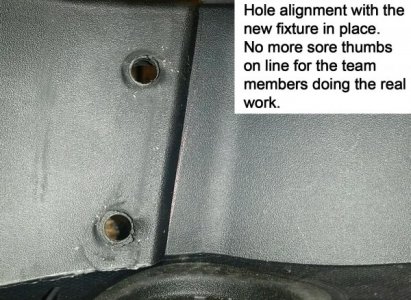

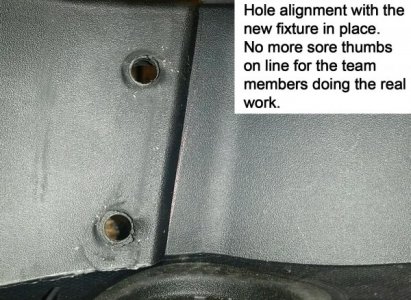

Problem was the fixtures used to locate the drilled holes were made with no adjustability for dialing in the hole locations relative to each other. We ended up with misaligned holes which gave the folks on the floor sore thumbs pushing in the pins.

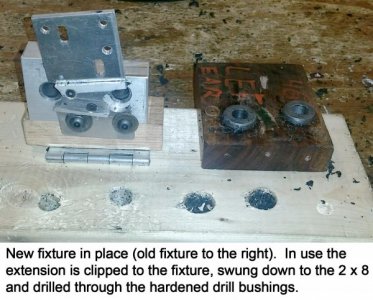

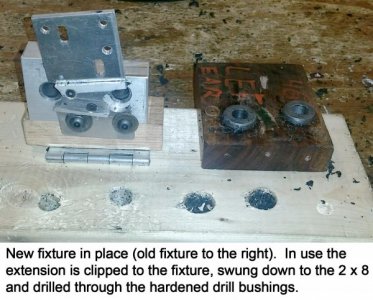

The extension attaches to the cowl with a couple of clips. Idea was to make a plate that would net to the clips for locating. The drill bushings would be in a block which is adjustable to the clip plate through a couple of over-sized bolt holes. Once the holes were dialed in, the clip plate and block would be pinned together.

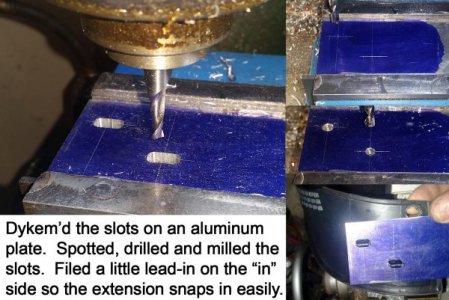

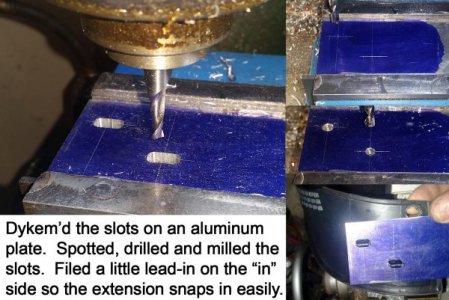

Measured the clip locations on the extension and marked the locations on a plate of aluminum. Spotted, drilled and milled slots for the extension clips. Made the drive bushing holder from a block of aluminum.

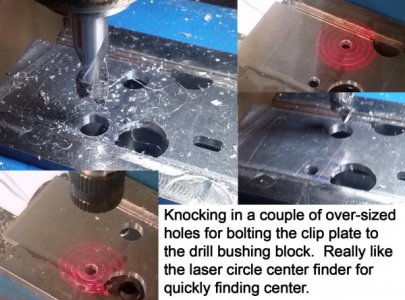

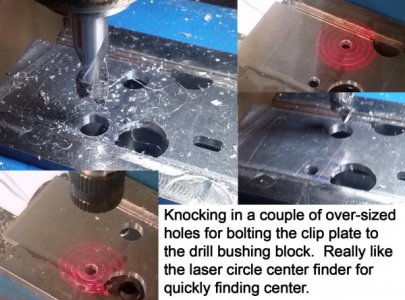

Next, machined clearance holes in the clip plate for the extension drilling operation. Also drilled in a couple of over-sized holes for attaching the clip plate to the drill bushing block. I’m starting to warm up to my SDA laser center finder which projects a series of concentric circles. I’m able to hit better than 0.007” to center, really goes quickly with the laser as compared to an indicator sweep or co-ax indicator. I didn’t show the operations, but attached a wood block to the bottom of the fixture for screwing to a hinge on the rework table.

The drill bushings were made from a length of 1” drill rod. Turned a shoulder, drilled a rough center hole and reamed to size (clearance for a 12 mm drill bit). Then bored the hole to size and added a lead-in for the drill bit with a MT2 reamer. Hardened them on the weld bench with an oxyacetylene torch and oil quench.

In use, an extension is clipped to the fixture, then swung down to a board for drilling. Ran a few parts and tweaked the alignment before drilling a couple of 1/8” dowel pin holes to lock the clip plate and drill bushing block to each other.

Works great by the way. Folks on the floor are happily going home without sore thumbs, plus the fit of the extension to the cowl is spot on.

Thanks for looking.

Bruce