-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2018 POTD Thread Archive

- Thread starter 2volts

- Start date

- Joined

- Nov 23, 2014

- Messages

- 2,609

Actually, no duct tape used in our production! There's an interior flammability FMVSS requirement for burn rates of less than 4" per minute. Duct tape just doesn't cut it!So Bruce, Chevs are held together with Duct tape. Just joshing.

Greg

Bruce

- Joined

- Nov 23, 2014

- Messages

- 2,609

Hi John,Durn, Bruce! I thought a "government" job was something you did for yourself at the factory. You've turned the definition upside down.

Nice save!

I was thinking the same thing . . . spending my time fixing something for work?!?! Not a big deal, let's me walk through any area of our plant and not have to dodge anyone. Folks on the floor know my group has their backs, we're all on the same team.

Bruce

- Joined

- Nov 23, 2014

- Messages

- 2,609

POTD was a quick repair on one of the supports for our pop-up camper. We bought the camper new in 2003 and haven’t used it for 7 years. So, finally got off my can and got it cleaned up for sale (SOLD!!!). As an aside, I’ve been successful discouraging mice from setting up shop by leaving the camper set up and every compartment open. Mice are a prey animal looking for food and shelter, no place to hide with everything set up and open.

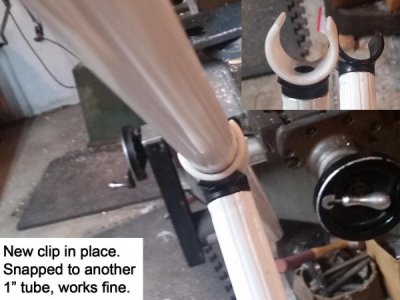

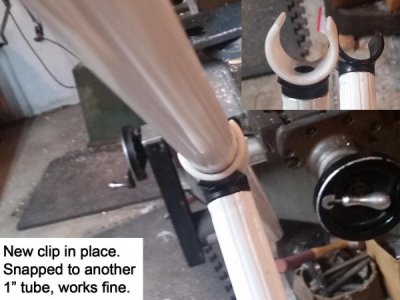

When I broke the camper down for moving it from the back of our pole barn to the shop side, noticed one of the “shepherd’s hooks” that supports the pull-out tent end had a broken clip on the end.

Measured up the intact one: 1” ID, 1 ¼” OD, 1” wide. Chucked up a piece of 1 ¼” Delrin and drilled it out to 1”. Parted and cut it into a “C” section on the band saw. Drilled a clearance/countersink for a 10-24 flat headed screw. Drilled/tapped the existing insert and ran the screw.

Folks are picking up the camper this afternoon! Yeah, frees up about 8’ x 25’ in our pole barn. Plenty of space for a Do-all 24” band saw!

Thanks for looking,

Bruce

When I broke the camper down for moving it from the back of our pole barn to the shop side, noticed one of the “shepherd’s hooks” that supports the pull-out tent end had a broken clip on the end.

Measured up the intact one: 1” ID, 1 ¼” OD, 1” wide. Chucked up a piece of 1 ¼” Delrin and drilled it out to 1”. Parted and cut it into a “C” section on the band saw. Drilled a clearance/countersink for a 10-24 flat headed screw. Drilled/tapped the existing insert and ran the screw.

Folks are picking up the camper this afternoon! Yeah, frees up about 8’ x 25’ in our pole barn. Plenty of space for a Do-all 24” band saw!

Thanks for looking,

Bruce

- Joined

- Nov 23, 2014

- Messages

- 2,609

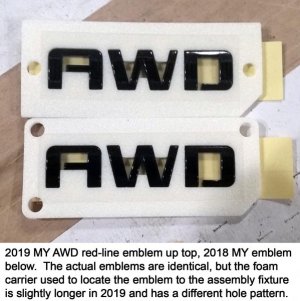

Another “government job” POTD. Model changeover from the 2018 MY to 2019 MY drives many subtle changes to our Chevrolet Traverse produced at the Lansing Delta Township Assembly Plant.

One part changing slightly is the “AWD” red-line emblem that goes on the lift gate of the Traverse. The emblems are applied by setting the part into a nesting fixture, peel off a backer film exposing the emblem’s adhesive, wipe the car with a lint-free cloth, set the locating fixture to the car, wet out the emblem and remove the fixture.

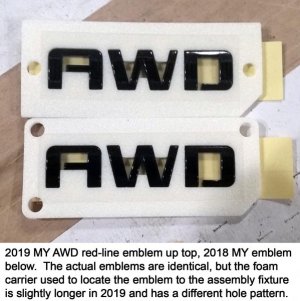

The location is changing from the 2018 MY to 2019 MY so for error-proofing, the 2019 MY emblem has a slightly larger foam carrier and a different hole pattern. The new hole pattern matches a chromed “AWD” emblem so common fixturing can be used.

Problem is we will have about 4000 2018 MY emblems left over. The emblems are identical, but 2018 MY emblems won’t fit on the 2019 MY fixture because of the foam size and hole location changes.

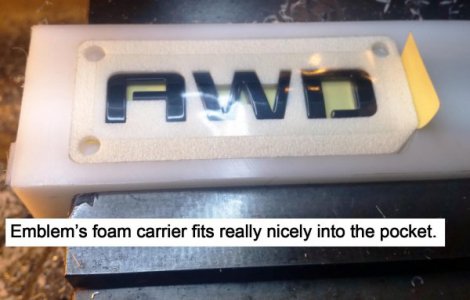

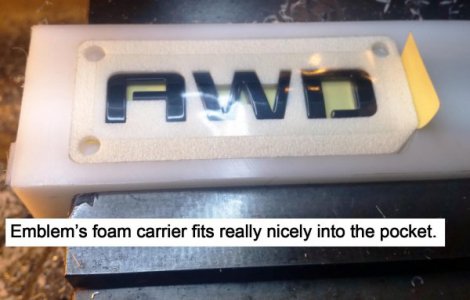

POTD time to keep from throwing away 4000 emblems. The 2018 emblems could be used in the 2019 fixture if they had the latter’s hole pattern added. Started by making a holding fixture from a block of Delrin. Wrote a CNC routine for my BP to do the profile. Then spotted and drilled a couple of holes for a hollow-core punch to knock in the two additional holes.

Came out really nice. The foam nests tightly into the block. In use a part is set in place, flipped over and set on a hardwood board. Then knock in the two additional holes with a hollow-core punch.

Thanks for looking!

Bruce

One part changing slightly is the “AWD” red-line emblem that goes on the lift gate of the Traverse. The emblems are applied by setting the part into a nesting fixture, peel off a backer film exposing the emblem’s adhesive, wipe the car with a lint-free cloth, set the locating fixture to the car, wet out the emblem and remove the fixture.

The location is changing from the 2018 MY to 2019 MY so for error-proofing, the 2019 MY emblem has a slightly larger foam carrier and a different hole pattern. The new hole pattern matches a chromed “AWD” emblem so common fixturing can be used.

Problem is we will have about 4000 2018 MY emblems left over. The emblems are identical, but 2018 MY emblems won’t fit on the 2019 MY fixture because of the foam size and hole location changes.

POTD time to keep from throwing away 4000 emblems. The 2018 emblems could be used in the 2019 fixture if they had the latter’s hole pattern added. Started by making a holding fixture from a block of Delrin. Wrote a CNC routine for my BP to do the profile. Then spotted and drilled a couple of holes for a hollow-core punch to knock in the two additional holes.

Came out really nice. The foam nests tightly into the block. In use a part is set in place, flipped over and set on a hardwood board. Then knock in the two additional holes with a hollow-core punch.

Thanks for looking!

Bruce

- Joined

- Sep 2, 2013

- Messages

- 5,121

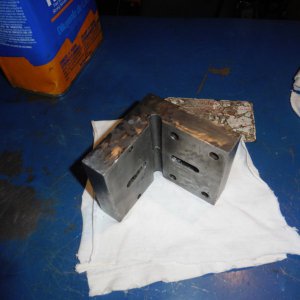

Got this 4x4 angle plate in a box of tooling. It was filthy, and pretty beat up. First into the parts washer for a good scrub, then into the bead blast cabinet for stain removal. There were four tapped 5/16 holes that were filled with what I assume was old cutting oil, but had the consistency of semi-melted rubber, and very tough to get off the fingers. Why is it that I can be wearing a pair of latex gloves most of the day, and as soon as I get into something really nasty they seem to have magically disappeared? Used a drill bit, carb cleaner, and a bore brush and eventually got them cleaned out. Last step clamped it in the vice and flat filed all the nicks, and gouges on all the surfaces. Found a stamping on it "Made in USA by Challenge Machy Co New Haven Mich". Not really pretty, but now usefull. If/when I ever get a SG, I may try to make it more presentable. Didn't get a before pic, but you can see it here https://www.hobby-machinist.com/threads/my-tool-angel-comes-through-again.70450/ again.70450/ Thanks for looking, Mike

Last edited:

- Joined

- Nov 23, 2014

- Messages

- 2,609

Nothing special about the Delrin, material on hand. Have a box of blocks and rods about the size of a 10 ream paper box.I sure enjoy seeing the POTD jobs, i have a question i see you only use Delrin on them, is there a reason for using Delrin or just on hand.

Bruce

- Joined

- Oct 31, 2014

- Messages

- 444

I found a couple of Manfrotto monopods (a 1-legged camera stand that's really handy for supporting and stabilizing a still- or video- camera) on our local craigslist at a great price but one of them didn't have the essential knob to adjust or lock the tilt friction axis.

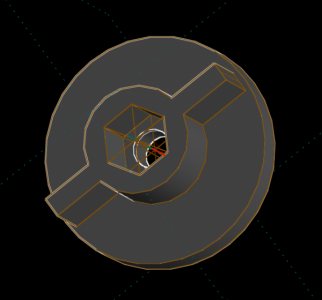

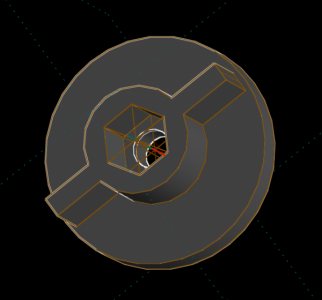

So I did some quick measuring, designed a knob in solvespace 3D and ran it out on the Prusa 3D printer.

10 minutes to design, a little under an hour to print and voila! Almost looks like factory original if you squint a bit!

3D design:

Printed Knob and 6mm bolt:

And the installed knob / bolt:

So I did some quick measuring, designed a knob in solvespace 3D and ran it out on the Prusa 3D printer.

10 minutes to design, a little under an hour to print and voila! Almost looks like factory original if you squint a bit!

3D design:

Printed Knob and 6mm bolt:

And the installed knob / bolt:

- Joined

- Feb 27, 2014

- Messages

- 2,130

10 minutes to design, a little under an hour to print and voila!

I love the 3D-Printer for stuff like this.