POTD was more shop organization. The first photo is what I started with; 15 years of clutter dumped on an 8’ x 6’ x 2’ deep shelving unit. In a previous POTD post I showed the first of two 4’ x 4’ x 2’ deep storage cabinets. Today’s projects included installing an 8’ long shelving unit over the cabinets and making plastic bin end/label pieces.

There’s a 1’ deep shelf just above the cabinets, then a 16” deep one above that and two 1’ deep shelves at the top. Naturally, the least used stuff ends up on the top shelf. I’ve got electrical boxes, plumbing fittings and tool box storage on top.

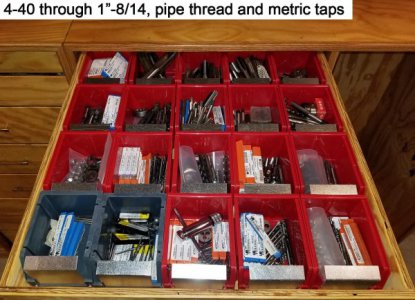

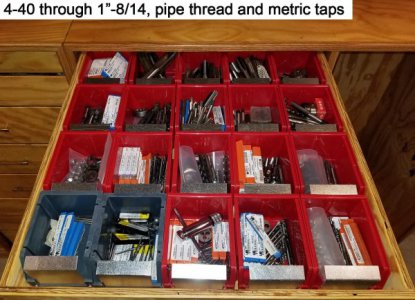

The cabinets have full-extension drawer glides so they pull out completely. The LH cabinet was made first and included drawers 10”, 8”, 3: 6”, 4” and 3” deep. I discovered the 4” drawers perfectly housed storage containers sold by HF and Menards. I had most of my cap screw and bolt hardware stored in plastic storage boxes with slide out drawers. Same for most of my taps. So the second cabinet got a bank of 4” drawers for the plastic bin organizers. The bins are stackable and have a 3” wide place in the front for a label. Problem for me was the fronts were buried in the drawers. I made a boat-load of 24-gauge galvanized sheet metal pieces 3” x 3” and bent an 80 deg. angle ¾” from an edge which slips into the label slot on the bins. Works great for providing a place on top for a label and closes off the open end of the bins.

I started labeling the bins with a Brother label maker but ran the paper/ink cartridge out, so will have to wait for another cartridge to finish the job. The pictures show the “machinist” hardware in the LH bank of drawers in the RH cabinet. The LH cabinet has stuff like soldering irons, auto hardware (pulley puller, spark plugs, Schraeder valve covers, etc.), nails, screws, tooling for the reproduction Erector set parts I make, electrical items (switches, plugs, Romex staples, etc.), cabinet hardware, etc., etc., etc.

Once the new label cartridge shows up the remaining bins and drawer fronts will get labeled. I still need to make the bank of drawers for the far right side of the cabinet. Once the dust settles I’ll see what’s left to store and make the appropriate sized drawers.

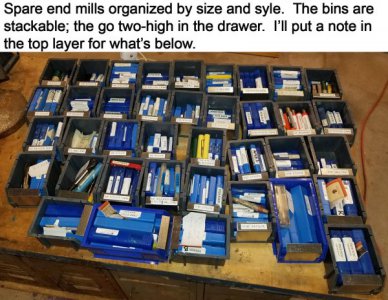

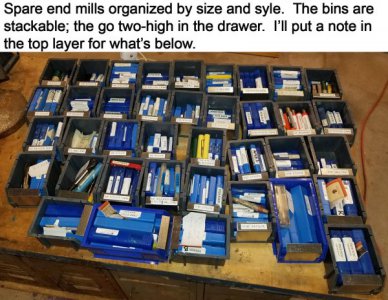

Really happy how things are working out. I had close to 500 new Niagra end mills stored in plastic bags by size, material (HSS, Cobalt, Carbide), flute, and style (ball end, rougher, conventional) that now set in one drawer. Granted, they are stacked two-high, but I have 4-flute HSS under 2-flute so the former are easy to find. I’ll throw a note in the top bins of the others to ID what’s directly underneath.

Thanks for looking!

Bruce