- Joined

- Apr 23, 2018

- Messages

- 6,551

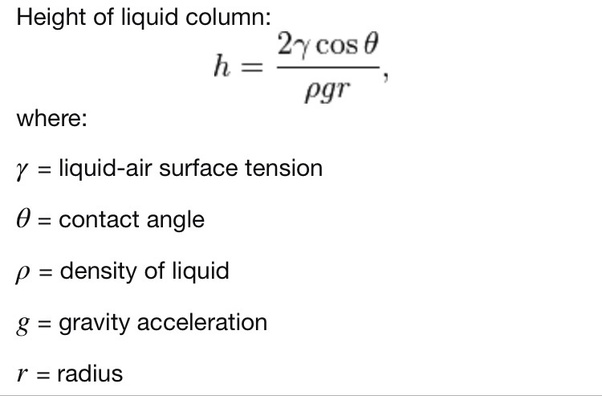

This is most likely the reason your epoxy ended up rising proud of the surface. High surface tension and a tight gap results in capillary action before the epoxy sets. A looser fit between the magnet and the recess would reduce this effect by increasing capillary radius. Just in case you were interested in some nerd trivia...Just the 5 minute epoxy that comes in the double syringe. Should have put a clamp on it, next time. Interesting phenomena with the JB Weld, will try and remember that one.

Greg