- Joined

- Nov 24, 2014

- Messages

- 3,185

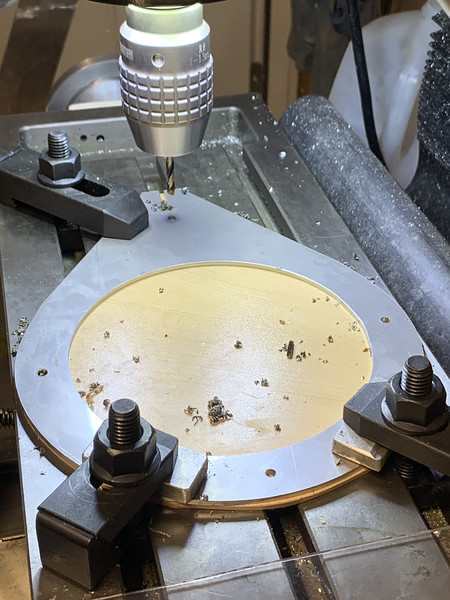

It’s not bad. Not the best by any stretch but perhaps better than some. I bought it from KBC Tools about a year ago and did a short post on some of the clean-up and modifications I made to improve the performance. You can find that here...

RT Rehab

Got the little rotary table tuned up enough to actually do something. This is the one I bought a few weeks ago and right out of the gate I knew I was going to have to put some time into it. I had intended to put together a more thorough play-by-play of what I did but it was starting to feel...www.hobby-machinist.com

I’ve used it a few times since and it performs alright. The added base section really adds functionality and is a must in my book for tight areas. There’s a short bit on it here...

2019 POTD Thread Archive

Bruce , I hope you visited him in Ireland ! My son went to U of Limerick for his Masters . We all visited the island for 2 weeks exploring all ends . Ireland is a very cool place I must say . :encourage:www.hobby-machinist.com

@extropic Thanks for the interest.

-frank

LOL . . . It turns out that everything that caught my eye and made the RT special, are bits that YOU made.

Nice work. Thanks for posting.