Project of the last couple o days.

Buying an old GMC motorhome and realizing it needed a lot of work underneath (sewer system, fuel tanks, wiring, etc) I invested in a suitable 4-post lift and at the same time figured the matching rolling jack would be useful so I got the package. I'm too old and creaky to be on my back on a creeper. Creaky creeper? Hmmm.

As it turned out, once it arrived and got set up I found that the rolling jack arms didn't go wide enough to get under the lift points of the coach. Advice: Check the specifications more carefully than I did. Would have saved quite a few of the green.

So, on to my project, making a set of replacement jack arms.

The lift is metric, all I could find nearby that was affordable (HRS) was either grossly undersized or very slightly oversized. Doing the math showed a suitable length arm would have to be pretty much full size in the rectangular lift tube and the nearest available Imperial size of CRS was exactly the (measured) height of the tube and slightly smaller in width.

Off to the metal supply - I needed two pieces about 39" long and it comes in 12' sticks. Best deal I could find was some very nice cold rolled steel. That's steel spelled with several $ signs by the way. The metal supply cut it into thirds so I could fit it into the back of the car, and I would cut it to fit exactly once I got it back and have the drops for who knows what future project.

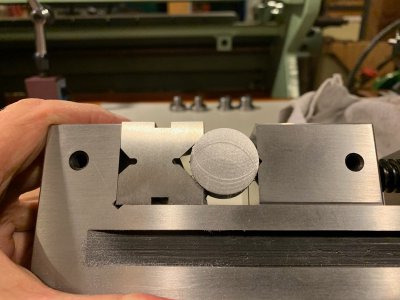

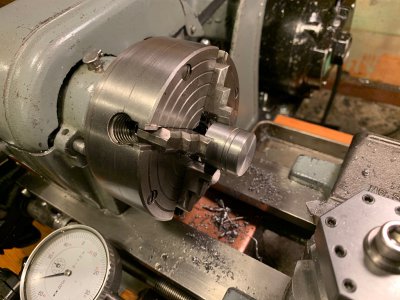

After cutting to length on the bandsaw and boring / milling the holes for the lift pads I did a test fit and found that the rectangular tube it was to fit into was a bit pinched where the welds of the gusset were. First thought was round the corners of the bar stock to give clearance for the weld distortions. It would also make the bars a bit nicer to handle in use without the sharp edges of the CRS. Off to the mill, and cut a 3/8" radius on the 2 long top edges and 3/16" on the bottom.

A good thought but the rectangular tube was also not particularly well dimensioned along its length (China fit and finish) and the replacement lift arms got 'stuck' a few inches farther into the tube. So, back to the mill, skive about 50 thousandths off the lift arms height where needed, add a bit of red paint (improved visibility instead of black to bonk your head on or trip over) and Bob's your uncle.

Whew!

Stu