The good first.

This shows where I put the Off/On switch.

Today I started with a 5 lb bar weight from Walmart to make the larger flywheel. I have used them before on another engine and was pleased with the results. At $6 and change you can't beat it.

After truing both sides I cut a 3 degree taper on the inside hole for the tapered bushing to fit into. I made the tapered bushing from 2" aluminum and slit the bushing so it would squeeze down onto the crank shaft when tightened. (Sorry no picture) I then mounted it on a shaft the same size as the crank shaft and finished the outer rim and cleaned it up on the lathe. I runs very true.

This picture shows it better installed on the crank.

What a difference I was able to start the engine by just flipping the flywheel and after some carb tuning I was almost ready to take another video.

Now the bad.

Into every life a little rain must fall and into every project there has to be an AW Sh*t.

I have been very lucky so far so I guess it was time.

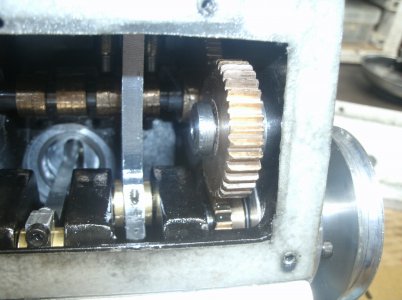

I could hear a sound from the rear of the engine like something would occasionally try to catch on something else and them release and be fine.

While I was trouble shooting the problem it got considerably worse and with one chunk the engine stopped.

I suspect the timing gears to be the problem but I said that is enough for today and closed the shop.

I am going to mow the grass tomorrow and just let things set before I disassemble the engine to see what went wrong.

Thanks for looking

Ray