- Joined

- Dec 18, 2019

- Messages

- 6,593

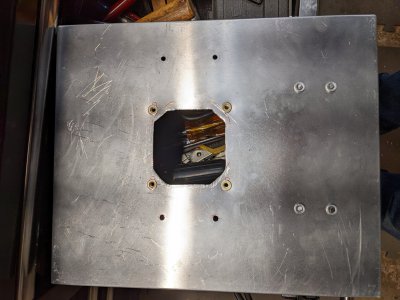

Hacked out holes for the fan intake and exhaust. Got the fan filter guards installed on both the cover and the back of the box. Used my recently aquired rivnut gun to set the M4 rivnuts for the grill guard. Got everything wired up, save for the LED and did a smoke test. Forgot to put in the stepper cables and the alarm light was blinking. Turned off the main power and plugged in those cables and after turning on the power things are ok. The 4A fuse on the 110V side didn't blow, due to inrush, so that's a relief. Also the lit mains switch was working, so that's a plus. Was a productive day in the shop - at least something tangible was done! Forgot to take a picture of the mounted fan grills, but they're not much to look at...