- Joined

- Dec 18, 2019

- Messages

- 6,538

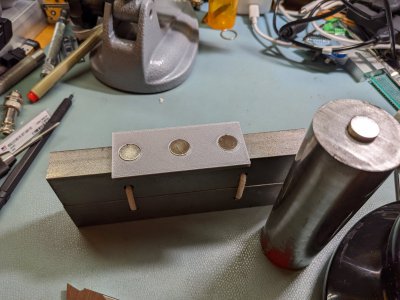

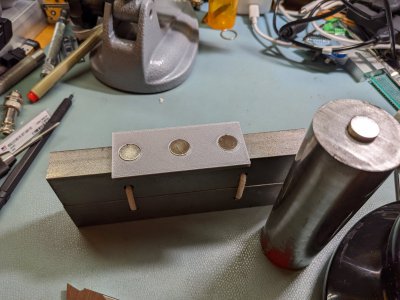

With the three N52 12mm diameter x 3mm thick magnets that I have, (found two more!) there's a rather high attractive force through the 0.8mm plastic. With a keeper across the magnets, through the 0.8mm plastic, it will easily pick up 1.439 kg. Without a keeper it cannot pick up the steel weights. Probably should use a pail and put in water or steel scraps to get a real difference. Of course the raw magnet side has noticeably higher force. Probably will print as is. Because my model is not truly parametric, when I change the wall thickness, there are some minor other changes.

Have to say, this plastic test piece is pretty strong. 3.6mm thick PLA, 15% infill, 77mm x 32mm. It doesn't break easily, I tried. If I put it in a vise and bent things, I'm sure it would break. Magnets don't want to come of the pockets, either! Had to use a sharp tweezers point through the 0.8mm plastic to push out the magnets.

Did an experiment. Without a keeper, cannot pick up 1.439 kg. With a keeper, the three alternating magnets pick up 2.484 kg. Nearly double. This is with three alternating magnets with a steel keeper across the raw magnet side.

Will not pick up the two attached rectangular pieces of 1018 without the keeper.

With keeper, will pick up both rectangular blocks (pipe cleanered together) and the piece of 1045 steel rod, just barely, but does pick it up. Weights measured were the two rectangular blocks without keeper, and the 1045 rod with magnet. I estimate about 7.28 lbs of retention force with 4 magnets and a keeper. The keeper is just a 3/8" key stock lathe tool model. Both cases, magnets were visible from the top, with a plastic layer underneath.

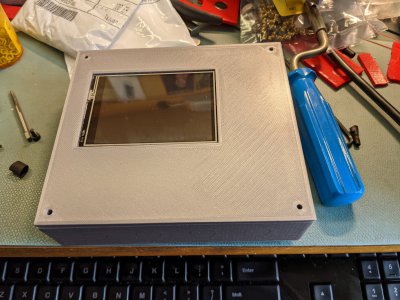

Probably print the box tomorrow. Might horse around with PETG tonight.

Have to say, this plastic test piece is pretty strong. 3.6mm thick PLA, 15% infill, 77mm x 32mm. It doesn't break easily, I tried. If I put it in a vise and bent things, I'm sure it would break. Magnets don't want to come of the pockets, either! Had to use a sharp tweezers point through the 0.8mm plastic to push out the magnets.

Did an experiment. Without a keeper, cannot pick up 1.439 kg. With a keeper, the three alternating magnets pick up 2.484 kg. Nearly double. This is with three alternating magnets with a steel keeper across the raw magnet side.

Will not pick up the two attached rectangular pieces of 1018 without the keeper.

With keeper, will pick up both rectangular blocks (pipe cleanered together) and the piece of 1045 steel rod, just barely, but does pick it up. Weights measured were the two rectangular blocks without keeper, and the 1045 rod with magnet. I estimate about 7.28 lbs of retention force with 4 magnets and a keeper. The keeper is just a 3/8" key stock lathe tool model. Both cases, magnets were visible from the top, with a plastic layer underneath.

Probably print the box tomorrow. Might horse around with PETG tonight.