- Joined

- Dec 18, 2019

- Messages

- 6,470

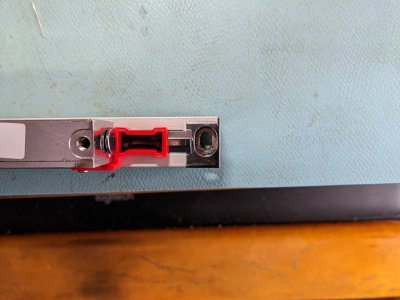

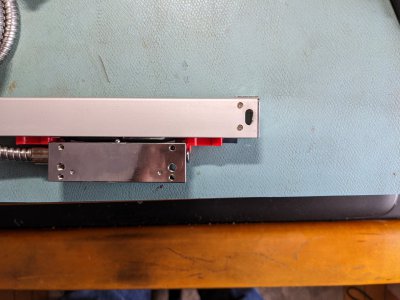

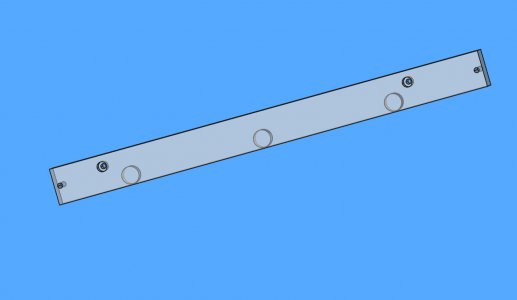

Got a little tired of the 0.001" resolution of the magnetic DRO's and ordered some 1um glass scales from AliExpress in mid January, pretty much just in time for Chinese New Years, when the whole country stops working. Got word today that the scales have left China and are passing through Narita, Japan. So they are on the way! My ELS can accommodate scales of 0.001"/div, 5um/div, and 1um/div. Doesn't care if you mix them up either. Making this ELS has been a great project involving electronics, software and machining, it was quite enjoyable.

In other, related news, I have created a private gitlab repository, and am working on getting it ready for testing. Did a successful burn of the code using the hosted code, so I am happy about that.

In other, related news, I have created a private gitlab repository, and am working on getting it ready for testing. Did a successful burn of the code using the hosted code, so I am happy about that.