- Joined

- Dec 18, 2019

- Messages

- 6,468

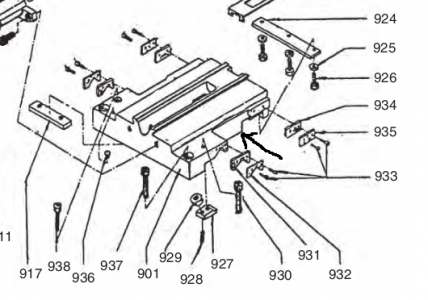

The bracket for the cross slide is done and mounted. Have to figure out how to mount the read head. Think I will pull the whole saddle off and mill the casting vertical. Right now there's about a 4-5 degree angle from vertical. That area is indicated by the black arrow.

Suspect I will have to slide off the whole saddle/apron off the end, after removing the lead screw bracket near the tail stock. That will be fun.

Suspect I will have to slide off the whole saddle/apron off the end, after removing the lead screw bracket near the tail stock. That will be fun.