-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Oct 24, 2013

- Messages

- 481

Very convenient device!

David Best has great installation info here:

www.flickr.com

www.flickr.com

(.....just some M5 x 30 SHCS keeping back the installation of the scales, will go get some tomorrow)

David Best has great installation info here:

Morton Quill Speed-Stop on PM935 Mill

This is a tutorial about how to change out the factory supplied quill depth stop on a J-head milling machine, and replace it with an upgraded version that has quick positioning capability. This particular depth stop is made of stainless steel in the USA by Morton Machineworks and is available...

(.....just some M5 x 30 SHCS keeping back the installation of the scales, will go get some tomorrow)

Last edited:

- Joined

- Oct 24, 2013

- Messages

- 481

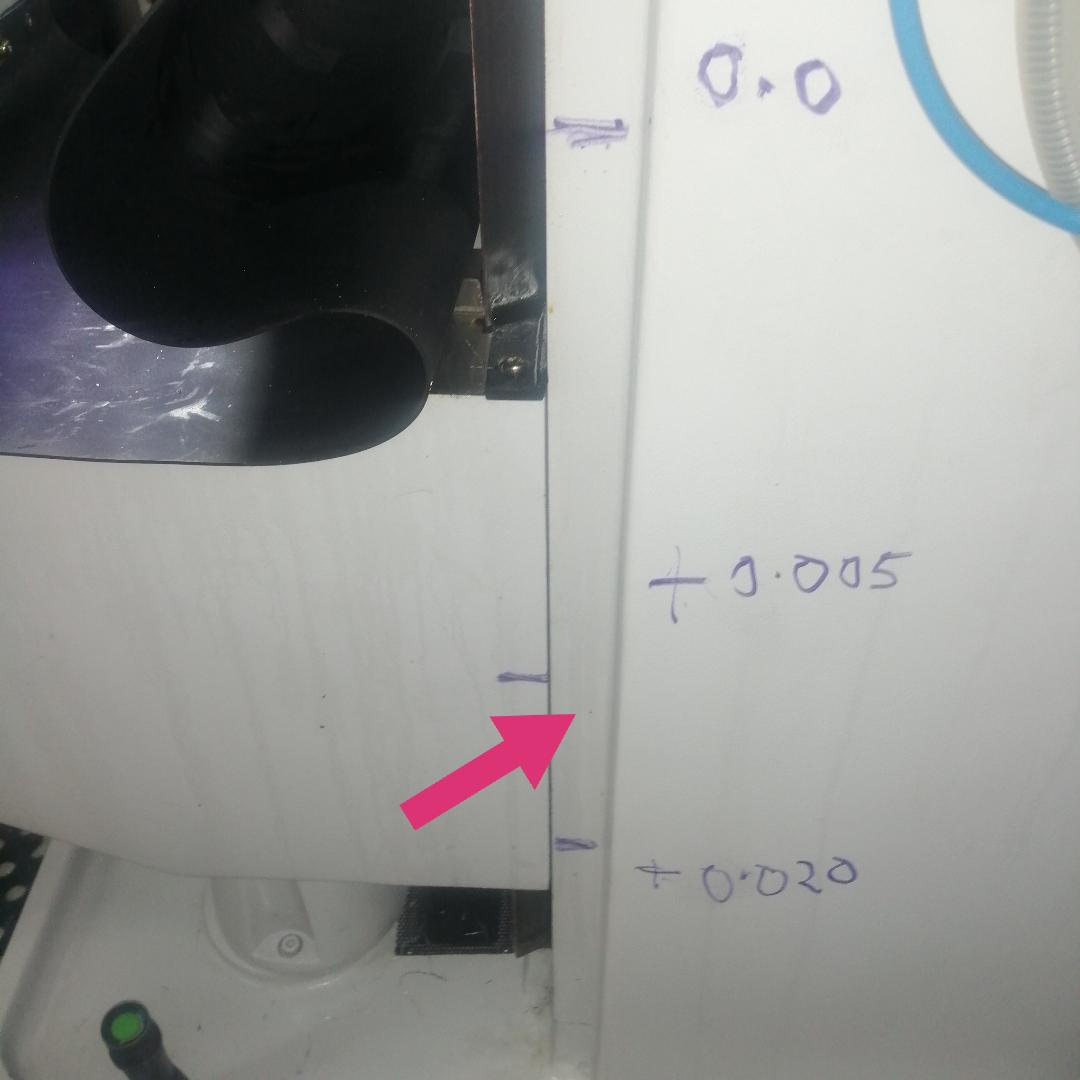

So, these are the very first parts made on the new mill. They are the standoffs for mounting the Z-axis DRO Scale rail. One is purposely made 0.020" shorter than the next for proper scale alignment.

The selected surface for mounting the Z scale:

The selected surface for mounting the Z scale:

Last edited:

- Joined

- Oct 24, 2013

- Messages

- 481

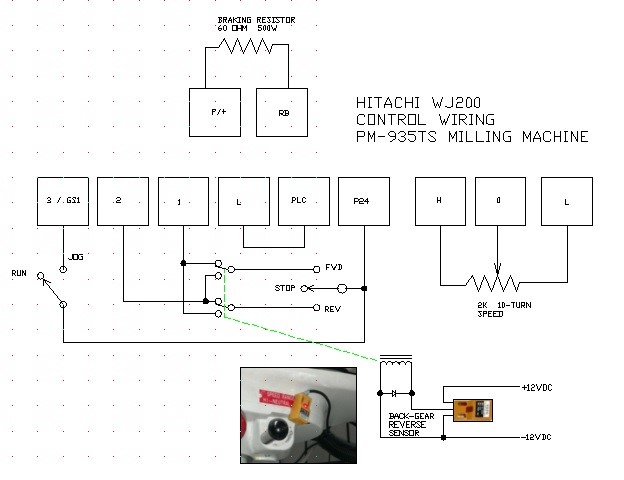

HITACHI VFD WJ200-022SF

Cletus’ Revised On-Machine Setup 2021/09/10

B037 = 01 Show All parameters

A082 = 230 Motor Nameplate Voltage

B012 = 11 Motor Nameplate Amperes

F001 = 60.00 Output Frequency Setting

A003 = 60 Base Frequency

A004 = 120 Maximum Frequency

A061= 120 Frequency Upper Limit

A062= 0.00Frequency Lower Limit

H004 = 4 Motor Poles

F002 = 3.00 Acceleration Time

F003 = 1.00 Deceleration Time

A001 = 01 Frequency Source (ext Pot) Pot on terminals “H”, “O”, and “L”

A002 = 01 Run External

C001 = 00 Set Fwd to terminal “1”

C002 = 01 Set Rev to terminal “2”

C003 = 06 Set JOG to terminal “3”

A038 = 4 Jog Frequency, 4.0 Hz

B031 = 10 High Level Access

B091 = 00 Stop Mode Selection

For braking resistor implementation add the following:

A042 = 5 Manual torque boost value (0-20%)

A054 = 60 %DC braking force for deceleration (0-100%)

A083 = 1 AVR filter time constant (0-10%)

B029 = .5 Deceleration rate of active freq. Matching (.1 to 3000.0)

B090 = 10 %Dynamic braking usage ratio (0-100%)

B092 = 01 Fan control

B095 = 02 Dynamic braking control (BRD) selection

B097 = 60 Should set automatically to resistor value

B131 = 390 Decel. overvolt. Suppress level

B133 = 1 Decel. overvolt. Suppress proportional gain

Cletus’ Revised On-Machine Setup 2021/09/10

B037 = 01 Show All parameters

A082 = 230 Motor Nameplate Voltage

B012 = 11 Motor Nameplate Amperes

F001 = 60.00 Output Frequency Setting

A003 = 60 Base Frequency

A004 = 120 Maximum Frequency

A061= 120 Frequency Upper Limit

A062= 0.00Frequency Lower Limit

H004 = 4 Motor Poles

F002 = 3.00 Acceleration Time

F003 = 1.00 Deceleration Time

A001 = 01 Frequency Source (ext Pot) Pot on terminals “H”, “O”, and “L”

A002 = 01 Run External

C001 = 00 Set Fwd to terminal “1”

C002 = 01 Set Rev to terminal “2”

C003 = 06 Set JOG to terminal “3”

A038 = 4 Jog Frequency, 4.0 Hz

B031 = 10 High Level Access

B091 = 00 Stop Mode Selection

For braking resistor implementation add the following:

A042 = 5 Manual torque boost value (0-20%)

A054 = 60 %DC braking force for deceleration (0-100%)

A083 = 1 AVR filter time constant (0-10%)

B029 = .5 Deceleration rate of active freq. Matching (.1 to 3000.0)

B090 = 10 %Dynamic braking usage ratio (0-100%)

B092 = 01 Fan control

B095 = 02 Dynamic braking control (BRD) selection

B097 = 60 Should set automatically to resistor value

B131 = 390 Decel. overvolt. Suppress level

B133 = 1 Decel. overvolt. Suppress proportional gain

Last edited:

- Joined

- Oct 24, 2013

- Messages

- 481

I fondly call it the "Nut-Cracker", cause if you leave it on, in all likelihood, the knee handle will crack your nuts when you use the motor drive!

Notwithstanding, just a simple device, cut crudely from HDPE flat-stock, that holds the knee crank engaged for hand adjusting Z-travel and quickly removed for motorized running (or, easily pulled out on your way to the floor, after your nuts have been indeed cracked!)

Notwithstanding, just a simple device, cut crudely from HDPE flat-stock, that holds the knee crank engaged for hand adjusting Z-travel and quickly removed for motorized running (or, easily pulled out on your way to the floor, after your nuts have been indeed cracked!)

Last edited:

I have a 935TV with most of the additions you've mentioned. I really enjoy working with (and on) this machine.

All I'm lacking is the Z-axis power feed and hooking up the mist collant system. That Z-axis feed is looking better and better to me.

All I'm lacking is the Z-axis power feed and hooking up the mist collant system. That Z-axis feed is looking better and better to me.