- Joined

- May 13, 2019

- Messages

- 1,016

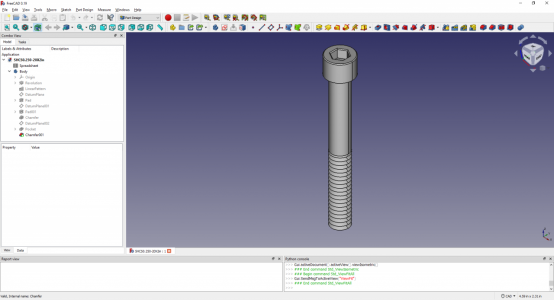

Do you stack disks, or do the revolve a sawtooth sketch, out of curiosity? Stacking disks, looks easier, but too inexperienced to know.For threads, I rarely make them correctly using a helix. The computations are really intense and FreeCAD slows down. Since I don't have a 3D printer, they don't need to be helixes.

I make them circular (round) and use the linear function to make as many threads as I need. They "look" correct, but really aren't.

Thanks. At the moment, I'm set up for mm. Trying to follow the videos, which are in mm. Since the drawing is actually for a metric tee-slot, might be ok to mostly keep it metric. Thank you for the tip in dimensioning, I will try that.I'm taking a look at, but things look confusing because you used mm in the spreadsheet and I'm set for inches. Do you intend to use mm's?

You can enter imperial dimensions in the spreadsheet by adding "in" after the dimension.

Thanks for clarifying an offset sketch. I'll try that.Maybe I used the wrong term, but an offset sketch is moved from its origin position. For instance, if you have a square 1" block and you want to put a hole on one face, you would pick a plane (such as XY) and use the position feature to move it 1" rather than sketch directly on the face.

Even when following this, I've seen some strange things happen in TechDraw when modifying the part. I just accept it and fix it.

I'm surprised that F360 is not offered on a Linux platform.

I would suggest removing the helixes from the part unless you are 3D printing it. Helixes are very complex computationally and will slow down FreeCAD considerably. If you look at the screw model I made, I just use circular rings to show where the threads are. Works fine.

Like I mentioned, I still struggle a bit with FreeCAD. But the more you use it, the better you get. I still have to search the web on occasion to do something.