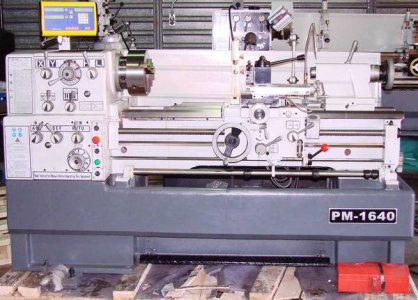

Hey Bill, yes I have information on that lathe from Matt at PM. The carriage stops are enticing on that lathe, its a step up from the G0509G but its also manufactured in China. The same lathe is sold under several importer brands, prices range from $9,500 to $10,500 so its priced between the G0509G and G0670. I decided that if I'm willing to go to $10k I may as well go all the way to the made in Taiwan lathes.

Matt also sells a RML 1640V which is equivalent to the Grizzly G0670 I'm considering. Again this same lathe is sold under several brand names, Kent for example. Right now nobody is even close to Grizzly on price, the G0670 is on sale $1,000 off for $13,495 plus $495 shipping. The next closest competitor is $3,000 higher price/shipping, though I'd probably not have to pay sales tax so that would save about $1,300. These Taiwan lathes are optioned somewhat differently. Matt's has a chuck and tool post shield. His are listed as ISO 9001 certified, Grizzly is not. Matt notes single phase power, I'm not sure that's the case for the variable speed model.

If Matt's RML 1640V is really ready to run on single phase power that might be a game changer, I'll have to buy a rotary phase converter to run the Grizzly which looks to be another $1,500 so that would.

I was able to speak with Grizzly this morning on the G0670 and confirmed some things. Motor is made in Taiwan, chuck is made in Taiwan, casting/bed is made in Taiwan. I had come across some postings on other brand lathes (not Grizzly or PM) where people were complaining that their made in Taiwan lathe turned out to be only partially made in Taiwan. The Grizzly looks to be 100% made in Taiwan so that's good. Matt's is further upgraded with Siemens electronics.

Closing out the G0509G its officially crossed off my list. I was able to speak with a few G0509G owners, it was mixed reviews but mostly positive. Most were happy overall, one noted its way more lathe than his 1440's. All noted a few quality issues and all owners noted the same issue with selection knobs/levers left you feeling unsure if they were positioned correctly. One owner obviously received a lemon unit and he wasn't happy.