Thank you extropic

I actually had the 2 piece set saved in my list for future purchase. I ordered both. It will take a few days to get so I will look at cutting something as you suggested. I should be able to use the RT for that, yes? Cut angle and trim top/outer and bottom/inner to approx dimension of the slot?

Thank you

Yes regarding the RT.

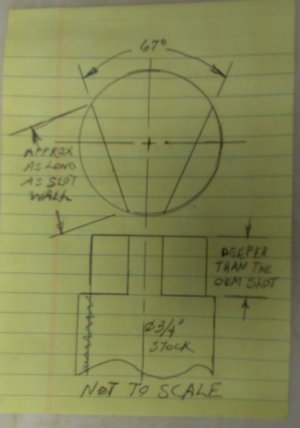

I'm not sure what the bold statement means. What I was trying to describe was making a pie wedge with 67° included angle. By using 3/4" stock it wouldn't be difficult to make it an overall size that will fill the OEM slot.

By the way, I haven't seen the need for the .760 diameter counterbore to be included in your new parts. I suspect it is an artifact of the OEM casting tooling configuration and doesn't serve any function on the mill. Unless you see a need for it, I would not reproduce it on the new parts.

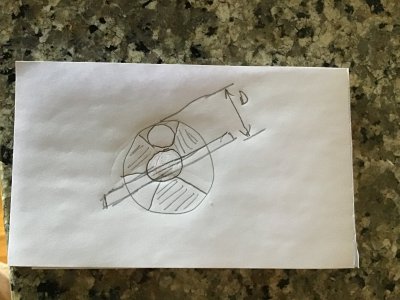

Also, because the grooves on the handle are wider than the protrusions, the opposite is true of the mating part. if we call the handle configuration the female (larger grooves) and the mating parts are the male (larger protrusions), then the extensions that you are intending to machine are male-female adapters. Not the same configuration on both ends. Right?

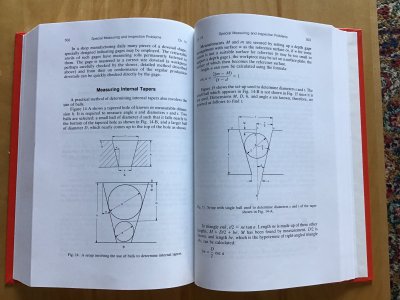

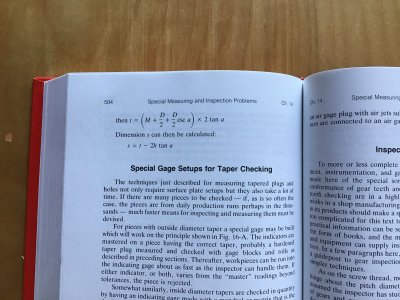

One last thing (for now) that I've been wondering about. So far we've been dealing with radial angles but we haven't talked about axial angles. What I want to know is whether or not there is axial taper in the planar walls of the protrusions/slots. When you mate/demate the handles, do you see increasing radial clearance (axial taper) between mating grooves/protrusions as you withdraw a handle or is the clearance constant (axially parallel)? If there is axial taper, the parts should mate with zero clearance on the axial faces. If the faces are parallel to the central (leadscrew) axis, the slip fit clearance is always present. let me know.

The pie wedge gage I have described should highlight any axial taper in the handle because the pie wedge will have none. Therefore, showing snug fit at the bottom of slot with visible clearance at the top.

PS: Determine the correct size of the pins (did you earlier say roll pins?) so you are prepared to remove and replace the mating part on the leadscrew(s). I would expect you could get them at a good ACE Hardware. You can certainly order them from McMaster-Carr. If you're not yet familiar with McMaster, you should be soon. They have an excellent web catalog and ordering/fulfilment process. If you know what search terms to use, you can probably find it at McMaster. Well, not everything.

Remember how easy/simple it was going to be?

Hang in there.

Hang in there.

Hang in there.