- Joined

- Apr 23, 2011

- Messages

- 2,476

Alright everybody, getting near the end here....

Looking forward to it. Not the end, just the completed project!

Cheers Phil

Alright everybody, getting near the end here....

That's looking good, Andre. Really good.

Looking forward to it. Not the end, just the completed project!

Cheers Phil

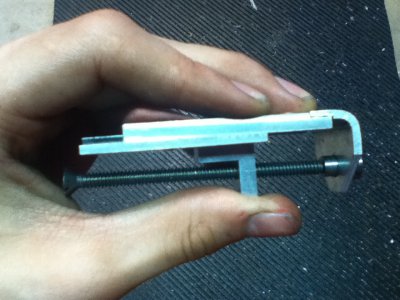

Here is my oops. Some people say this is a machinist's signature.....So yes, I guessed I signed this one LOL

View attachment 79882

Those oops monents will will always be present Andre, they may come fewer and further between as the years go by but every now and then you'll be saying to yourself, I can't believe I just did that..!:thinking:

Your lathe looks really good... Keep up the good work....!)

looking real good!!

Andre,

I notice you do a lot of "turning" on your mill. Do you not have a lathe?

Cheers Phil