-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just bought an old 1994 -12 X 36 Enco Lathe 110-2075

- Thread starter Mr Mike

- Start date

- Joined

- Jul 30, 2017

- Messages

- 475

I really like McMaster-Carr for their detailed descriptions, easy search, and no BS ordering. Often get stuff the next day and shipping is reasonable.

John

Thank you.. perfect.

Have any plexiglas bits fallen into the apron gears?

Hello, I Just found that along with a few other issues while cleaning and doing a complete once over after purchase. I don't believe so. Maybe I should fashion one out of aluminum.

Lol I could have avoided all this if I had patience to wait for the PM 12 X 28 to arrive, oh well pros and cons of life...!

Another source is Digikey.com, though be prepared to have your head explode, as there is such a thing as too much to choose from.

Oh yes Digikey is a monster, But I doubt even they will have an exact replacement bus system. thanks for the heads up sir.

- Joined

- Jul 30, 2017

- Messages

- 475

- Joined

- Jul 30, 2017

- Messages

- 475

Good morning all...

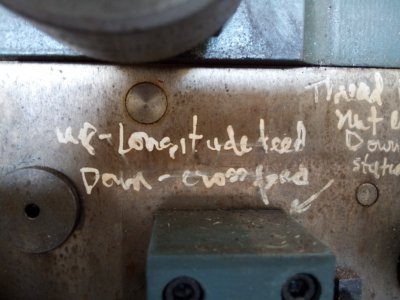

I would like to get this face plate reprinted, I was thinking of using my Graphics program to recreate this in detail but I have no idea who can print this back onto the aluminum so I can keep the stamped date and serial number...

The previous owner of the lathe used paint or a sharpie to blackout the Enco Logo, and made in china text, no idea why. I'm sure if i print this out on a plastic sheet it wont last long... any Idea who does this sort of work...? Thanks for looking.

I would like to get this face plate reprinted, I was thinking of using my Graphics program to recreate this in detail but I have no idea who can print this back onto the aluminum so I can keep the stamped date and serial number...

The previous owner of the lathe used paint or a sharpie to blackout the Enco Logo, and made in china text, no idea why. I'm sure if i print this out on a plastic sheet it wont last long... any Idea who does this sort of work...? Thanks for looking.

- Joined

- Jul 30, 2017

- Messages

- 475

The motor is all clean up, reinstalled and tested... I even splurged and upgraded to a new belt. There is still tons of cleaning left to do on the lathe, I've already spent the weekend cleaning and just barely made a dent in it...

Also I am going to buy the reprinted manual for this lathe, and I'm in need of a simple beginner lathe hand book too. It's kinda funny.. Size wise this 12 X 36 lathe is to my 9 X 20 what the 9 X 20 was to my 7 X 14 lathe, It seems like a really big leap in size, and the fit and finish isn't so bad on this lathe.

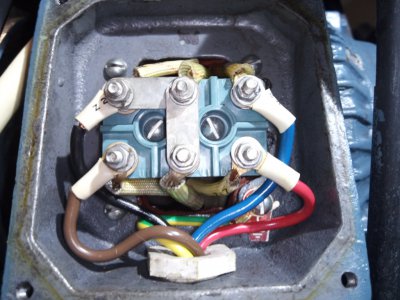

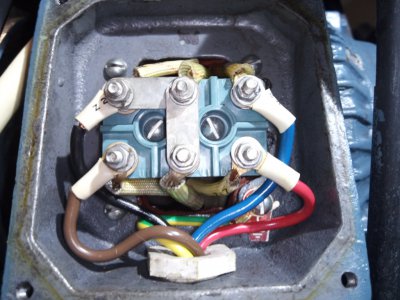

I thought it would be a good Idea to post a nice clear photo for other Enco people with this same motor to see the motor wired for 220V with easy to identify color coding purposely adjusted for clarity in the photo.

Also I am going to buy the reprinted manual for this lathe, and I'm in need of a simple beginner lathe hand book too. It's kinda funny.. Size wise this 12 X 36 lathe is to my 9 X 20 what the 9 X 20 was to my 7 X 14 lathe, It seems like a really big leap in size, and the fit and finish isn't so bad on this lathe.

I thought it would be a good Idea to post a nice clear photo for other Enco people with this same motor to see the motor wired for 220V with easy to identify color coding purposely adjusted for clarity in the photo.

- Joined

- Jul 30, 2017

- Messages

- 475

Hello all..

I'm in need of Tips & Tricks advice, whats the best cover for the lathe, it will be sharing space with other Wood Machine Tools... Not to mention this is Las Vegas, A warm dry dusty environment.. I would like to keep the lathe as ready for use as possible after sitting clean an all oiled up..

I'm sure the ways oil will attract wood and dust while sitting...? And i'm sure others have the same issue and solution, any suggestions would be appreciated.

Thanks Mike

I'm in need of Tips & Tricks advice, whats the best cover for the lathe, it will be sharing space with other Wood Machine Tools... Not to mention this is Las Vegas, A warm dry dusty environment.. I would like to keep the lathe as ready for use as possible after sitting clean an all oiled up..

I'm sure the ways oil will attract wood and dust while sitting...? And i'm sure others have the same issue and solution, any suggestions would be appreciated.

Thanks Mike

Any cover that is large enough and breaths should work. I prefer the flat style as opposed to a fitted one because it is easier to put one and remove & fold. A synthetic fibre would absorb less oil than a cotton bed sheet for example. I use a retired fly sheet from a tent that does not breath, But my shop is climate controlled so there is no condensation. Las Vegas should be dry enough not to have to worry about condensation either.

- Joined

- Jul 30, 2017

- Messages

- 475

Hello all... The lathe is coming along, I am currently stuck on Roll Pins and their removal...

So I need to remove some roll pins that hold parts to this lathe, such as but not limited to the cross slide handle, there is not any chance on this planet that I'm using a hammer to remove it, I have a couple ideas for making a tool to gently remove them but why reinvent the wheel... so I thought surely others have had this problem solved.

If you happen to know the trick and like sharing please post it here... thank you.

If not Ill just drill out a C clamp and turn it into a Pin pusher, then after the lathe is all back together ill make a tool just for that.

So I need to remove some roll pins that hold parts to this lathe, such as but not limited to the cross slide handle, there is not any chance on this planet that I'm using a hammer to remove it, I have a couple ideas for making a tool to gently remove them but why reinvent the wheel... so I thought surely others have had this problem solved.

If you happen to know the trick and like sharing please post it here... thank you.

If not Ill just drill out a C clamp and turn it into a Pin pusher, then after the lathe is all back together ill make a tool just for that.