- Joined

- Nov 24, 2014

- Messages

- 3,173

@Rich Henderson

First of all, thanks for becoming a Life Member.

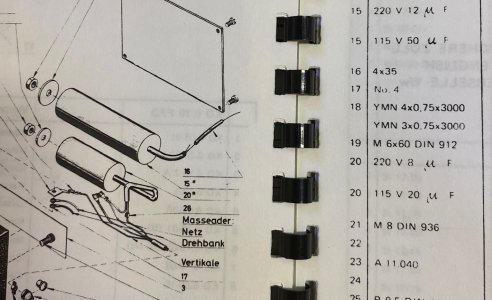

I've taken another look at the "what is it" photo and I have a revised opinion regarding the row of cylinders.

IMO, they are all threading die holders (not dies for punches). I now see a setscrew in the OD of a few (for securing the die). I think the through hole is to align the die, better than just using a naked die, coaxial with the workpiece. Sometimes it can be tricky to get such a die to cut coaxial. I think you'll find each through hole is the nominal ID of the intended thread's major diameter. The OD is probably intended to be held in a larger die stock or ???.

First of all, thanks for becoming a Life Member.

I've taken another look at the "what is it" photo and I have a revised opinion regarding the row of cylinders.

IMO, they are all threading die holders (not dies for punches). I now see a setscrew in the OD of a few (for securing the die). I think the through hole is to align the die, better than just using a naked die, coaxial with the workpiece. Sometimes it can be tricky to get such a die to cut coaxial. I think you'll find each through hole is the nominal ID of the intended thread's major diameter. The OD is probably intended to be held in a larger die stock or ???.

Last edited: