- Joined

- Oct 28, 2020

- Messages

- 528

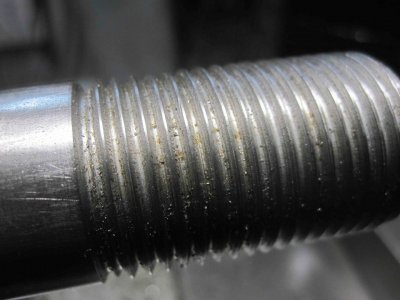

This week I worked on a paying gig to fab up some bushings. 6" long turned od and id with two thru holes 90 degrees apart. The only economical material is 2 1/2" heavy wall pipe. This pipe is no fun to work with, it is not round, has a seam and is generally nasty. I ordered a "pipe" or "bull nose" live centre, but the customer moved up the delivery date on me so I made my own. It is simply a slug of steel with a turned area (with tapered lead area) that is a "hammer it in" fit to the pipe on one side and a centre drilled hole on the other. It actually work quite well.

Here the ods have been done setting up for the ids

Turning the ids with my custom boring bar.

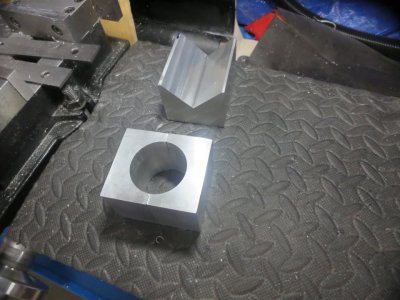

Here is a shot of the mill setup to drill the two 90 degree offset holes. I again fired up the Bostik260 to attache an indexing fixture to the end of the work. (I hot melt glued a 123 block to the end of the work).

* sacrificial parallel on the vice (also glued in place)

* work stop on left end

* square in position for indexing

All in all I'm glad to be done working with pipe for a while.

Thanks for looking.

Enjoy your shop time!

Here the ods have been done setting up for the ids

Turning the ids with my custom boring bar.

Here is a shot of the mill setup to drill the two 90 degree offset holes. I again fired up the Bostik260 to attache an indexing fixture to the end of the work. (I hot melt glued a 123 block to the end of the work).

* sacrificial parallel on the vice (also glued in place)

* work stop on left end

* square in position for indexing

All in all I'm glad to be done working with pipe for a while.

Thanks for looking.

Enjoy your shop time!