- Joined

- Feb 23, 2016

- Messages

- 424

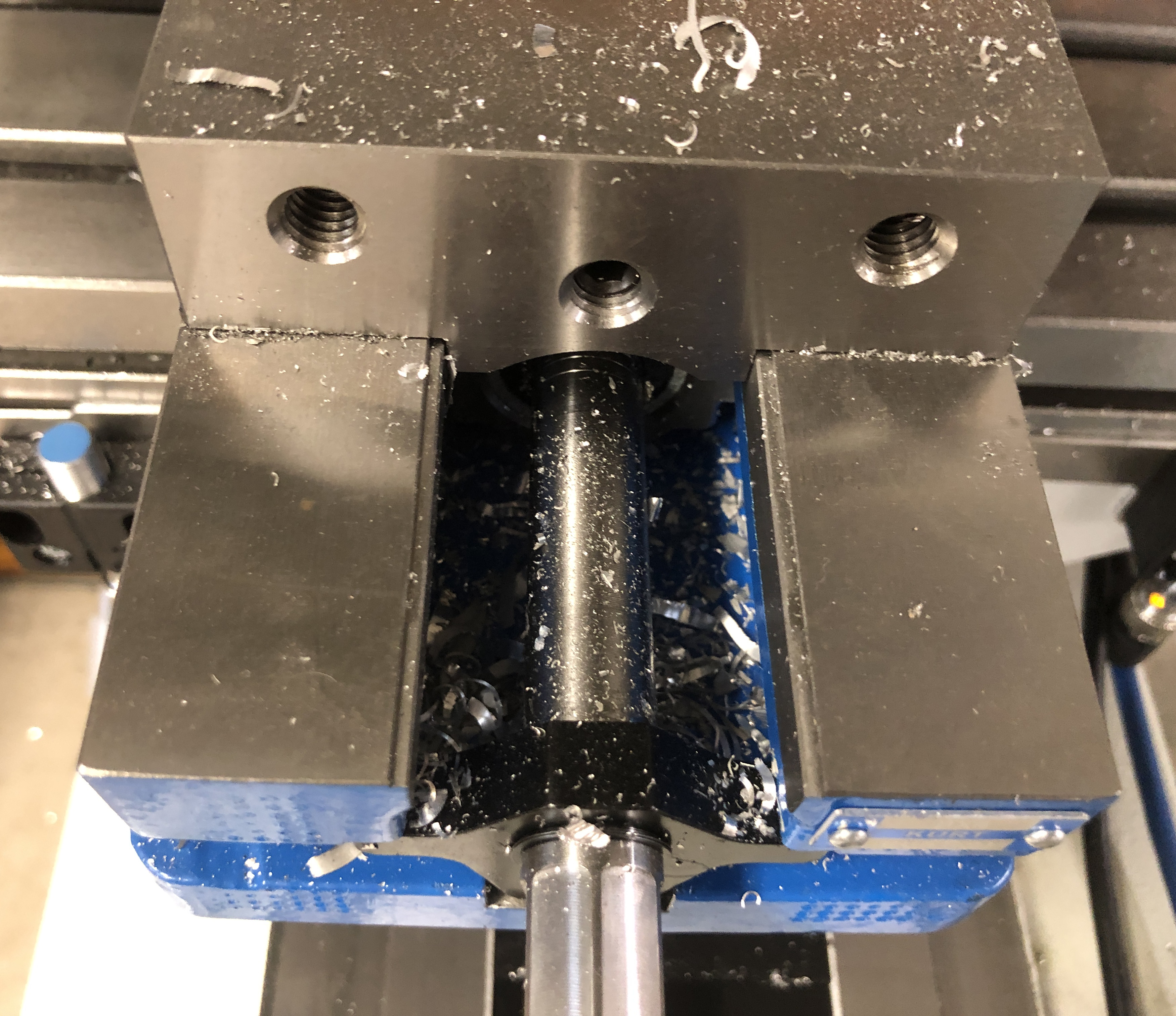

Can anyone guide me to a replacement bellows (accordion) -style way covers for both the z-and y-axes. The PM originals are pathetic.

I need some bellows for the 4" Kurt vise while I am at it. Thank you all.

I need some bellows for the 4" Kurt vise while I am at it. Thank you all.

Last edited: