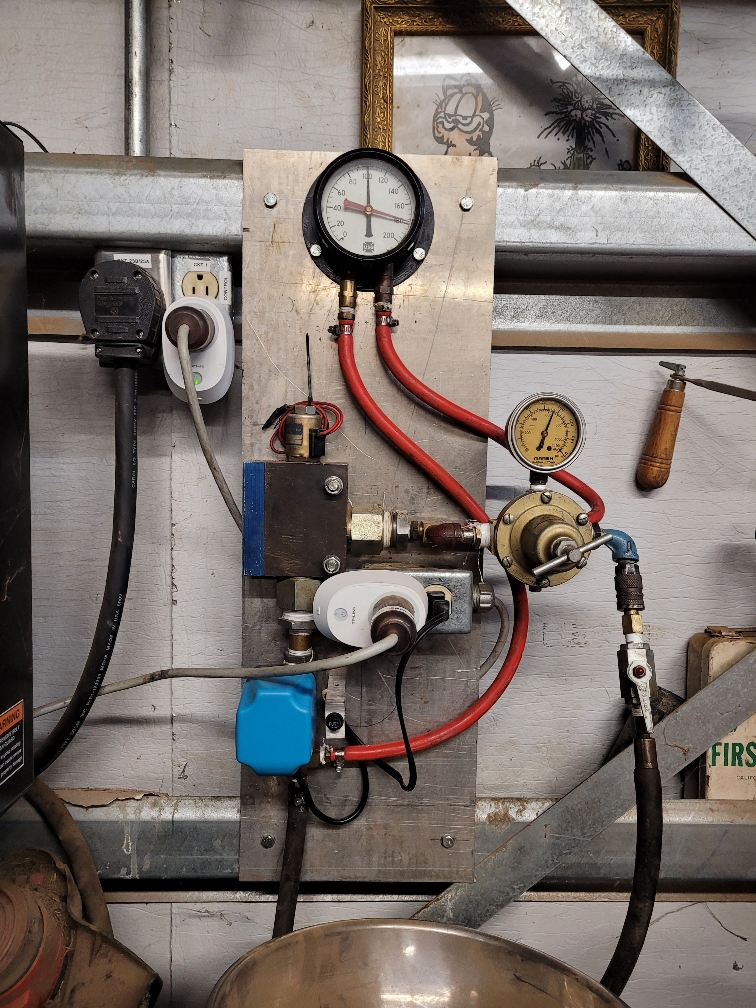

More updates to smart compressor control.

The control system for the air compressor had a solenoid valve to control the main air supply but we prefer a ball valve.

Looked up electric ball valve on Amazon and there were many.

After some time we found one that was simple, 120 VAC, Auto Return, Normally Closed, and 3/4 inch.

PERFECT!

It will go where the old valve was and we can get rid of the power adaptor that the old valve used.

We still have the ball valve on the tank as master some can do work with full tank.

The regulator still needs replacement as it has slow leak but that is another day.

We have an outlet that is connected to the lights located near the compressor.

When lights are on, outlet is on.

The compressor is magnetic starter so we added a relay with a 120 VAC coil that can control the starter via the power wire between the pressure switch and contactor

We added an outlet on a cord that is mounted to the panel.

A smart outlet plugs into the controlled outlet, Name is AIR

The panel outlet plugs into smart plug.

That ball valve power plugs into one of the outlets in the panel.

Another smart outlet plugs into the other side of the outlet, the relay plugs in here, Name COMPRESSOR.

With master ball on it is now easy, Alexa has good hearing so we can be at the normal work areas and control it.

Alexa AIR ON turns on the ball valve and power to other smart outlet.

Takes a bit to boot up, so to start compressor, Alexa COMPRESSOR ON and it goes.

Alexa can turn off or if we forget they go off with the lights.

The smart outlets do not remember to come on when power is returned no no surprise when we turn on lights.

No leak between tank master ball and the electric ball so if we forget to turn off master still have air.

Also can control with phone.

Compressor is 7.5 HP so we need not have it run when we are not there.

Sent from my SM-G781V using Tapatalk