-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fundamentals of Machining

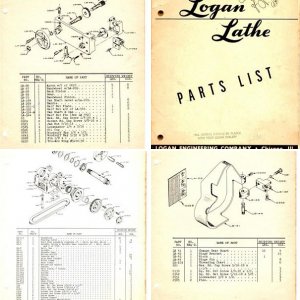

Scraping in all bearing surfaces on my Wards/Logan 10"

PIN

- 44,144

- 73

I've been working on my lathe off and on over the past several weeks or months, but I've been hesitant to start a thread documenting my progress (or lack thereof!) for fear of embarrassing myself. I'm increasingly confident that I'm going to end up with a very precise lathe rather than a very large pile of cast iron dust and tears, so I'm finally willing to share my progress. After creating...

KO-Lee Cutter/Grinder Revamp

PIN

- 33,344

- 93

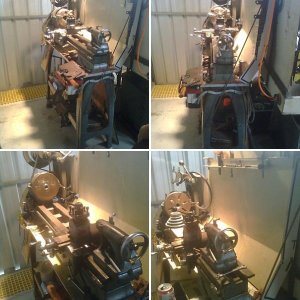

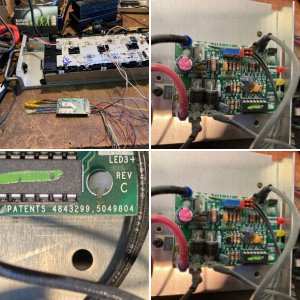

Perhaps you've seen this from other photos... It's a KO-Lee cutter grinder. It's a good platform and the table and all mechanisms are in excellent condition. I don't think this machine was used much in it's lifetime as there are very few signs of wear (hardly any at all really). The motor is the weak link. The bearings are going bad and vibration can be felt in the short shaft. The...

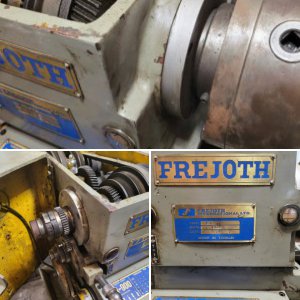

Restoring an old powered hacksaw

Jul 29

- 24,583

- 66

Figured I'd share my restoration project! I've always found these old machines quite cool and when a neighbour offered me a defective one for free, I couldn't say no!  This is the machine as I got it, it runs but won't lower the sawblade so you have to manually push it against the work piece, which becomes quite the challenge and dangerous as heck when it's moving back and forth. The...

This is the machine as I got it, it runs but won't lower the sawblade so you have to manually push it against the work piece, which becomes quite the challenge and dangerous as heck when it's moving back and forth. The...

9A project completed

Sep 11

- 36,666

- 67

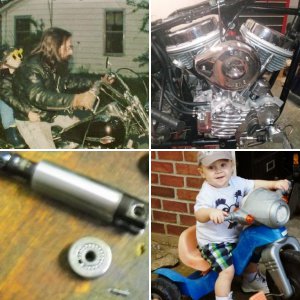

Some of you guys may remember this little crudball I acquired back in April... I had just completed the last project, the Seneca Falls #30 resto-mod,(project of the month) when this lathe found it's way to me via a friend of a friend. My friend, who is also a tool salesman, showed me a pic of this on his phone, which came from his friend, the seller, who now is a retired tool room...

Clausing 1771 Drill Press Restoration

Dec 23

- 24,432

- 31

I picked up a Clausing variable speed drill press from a Craigslist ad. I offered the guy $200.00 and he accepted. The drill press was in decent overall condition, and had a new motor on it. I disassembled the machine and cleaned up and painted everything. Mechanically, it was in very good condition, and the only real repair work I did was to straighten a few of the handle arms. One...

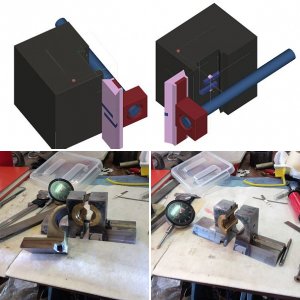

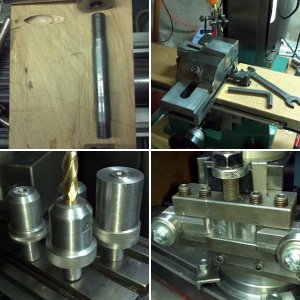

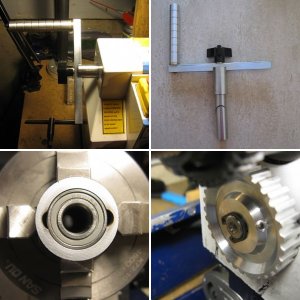

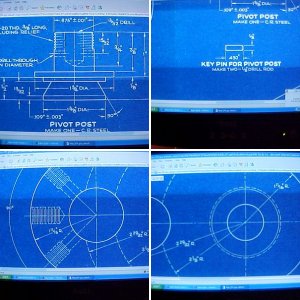

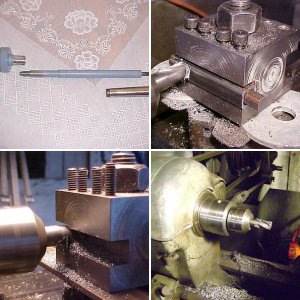

A Straddle Knurler for the Sherline Lathe

PIN

- 177,846

- 104

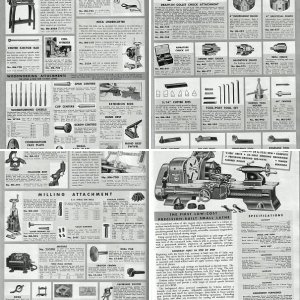

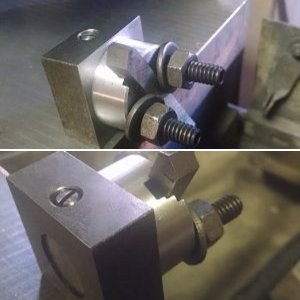

A Straddle Knurler for the Sherline Lathe The Sherline lathe is far more capable than most people know. I have explored the limits of this amazing lathe for the last 30 years and while I’m sure of what it can do, I am not so sure of what it can’t do because I’m still building tools for it. With the proper turning tools, it will take 0.120” off the diameter in mild steel or 0.200” in aluminum...

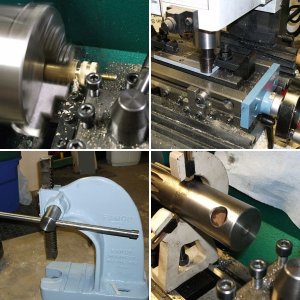

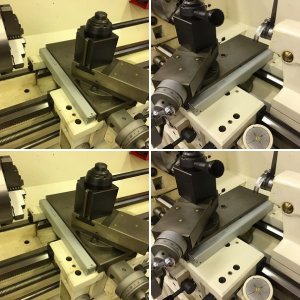

A Boring Primer

PIN

- 51,074

- 168

Boring on the Lathe for (New) Hobby Guys A Primer Being able to bore an accurate hole on the lathe is an important skill every hobby guy should have. We may not need to bore a precision hole all that often but when we need to, we should be able to. As we all know, that is easier said than done. I don’t know about you guys but when I started I didn’t really understand how a boring bar...

Oil Can #2

PIN

- 58,067

- 95

I was greatly inspired by Hackmasters beautiful oil can clone. I decided to do a run of my own with a simpler design. It was suggested that I start a new thread here and not hijack the other thread. The plan was originally solid brass. I realized that the pump housing would add too much weight so I went with an aluminum pump housing. I was sort of emulating this original as posted by...

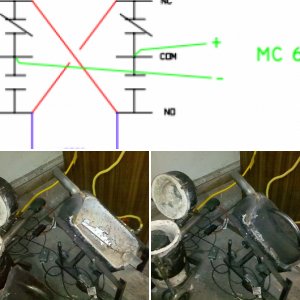

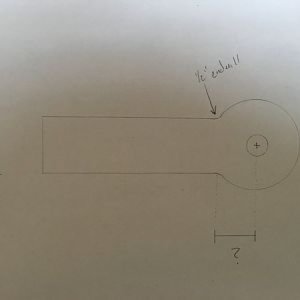

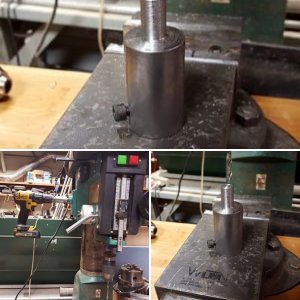

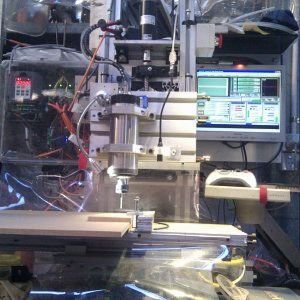

Quick & Dirty Worm Wheel making

Feb 01

- 5,064

- 15

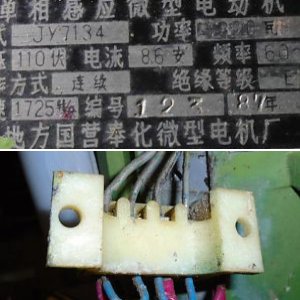

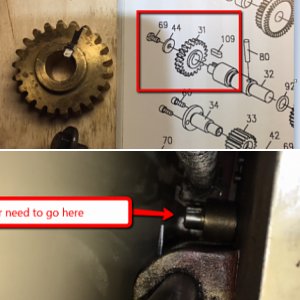

I was trying to make a substantial speed reduction to a small, but very powerful 230 Watt motor to drive a small auger. The motor specs are impressive Mabuchi Motor 12v Rs-775sf 230w 19500 rpm Model : RS-775 18V Weight : 11.9 oz Operating v : 6v - 20v Length of motor : 2.81 in Nominal v : 18v Diameter (with flux ring) : 1.85 in No Load RPM : 19500...