-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Projects and Articles by Our Members!

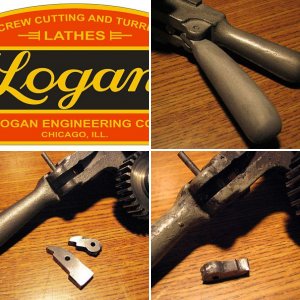

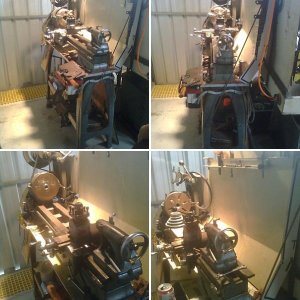

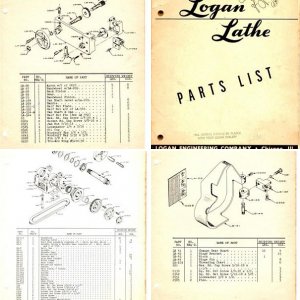

Scraping in all bearing surfaces on my Wards/Logan 10"

PIN

- 44,145

- 73

I've been working on my lathe off and on over the past several weeks or months, but I've been hesitant to start a thread documenting my progress (or lack thereof!) for fear of embarrassing myself. I'm increasingly confident that I'm going to end up with a very precise lathe rather than a very large pile of cast iron dust and tears, so I'm finally willing to share my progress. After creating...

KO-Lee Cutter/Grinder Revamp

PIN

- 33,344

- 93

Perhaps you've seen this from other photos... It's a KO-Lee cutter grinder. It's a good platform and the table and all mechanisms are in excellent condition. I don't think this machine was used much in it's lifetime as there are very few signs of wear (hardly any at all really). The motor is the weak link. The bearings are going bad and vibration can be felt in the short shaft. The...

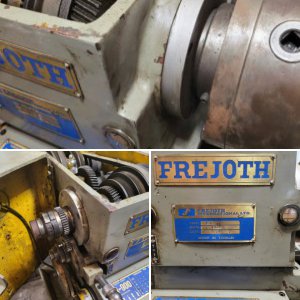

Restoring an old powered hacksaw

Jul 29

- 24,583

- 66

Figured I'd share my restoration project! I've always found these old machines quite cool and when a neighbour offered me a defective one for free, I couldn't say no!  This is the machine as I got it, it runs but won't lower the sawblade so you have to manually push it against the work piece, which becomes quite the challenge and dangerous as heck when it's moving back and forth. The...

This is the machine as I got it, it runs but won't lower the sawblade so you have to manually push it against the work piece, which becomes quite the challenge and dangerous as heck when it's moving back and forth. The...

9A project completed

Sep 11

- 36,668

- 67

Some of you guys may remember this little crudball I acquired back in April... I had just completed the last project, the Seneca Falls #30 resto-mod,(project of the month) when this lathe found it's way to me via a friend of a friend. My friend, who is also a tool salesman, showed me a pic of this on his phone, which came from his friend, the seller, who now is a retired tool room...

Clausing 1771 Drill Press Restoration

Dec 23

- 24,432

- 31

I picked up a Clausing variable speed drill press from a Craigslist ad. I offered the guy $200.00 and he accepted. The drill press was in decent overall condition, and had a new motor on it. I disassembled the machine and cleaned up and painted everything. Mechanically, it was in very good condition, and the only real repair work I did was to straighten a few of the handle arms. One...

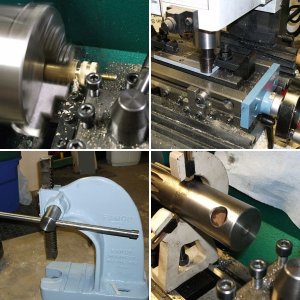

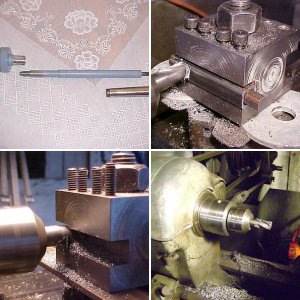

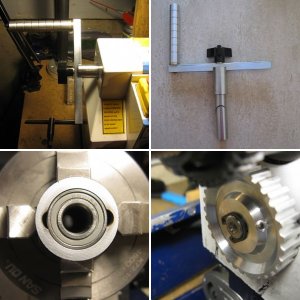

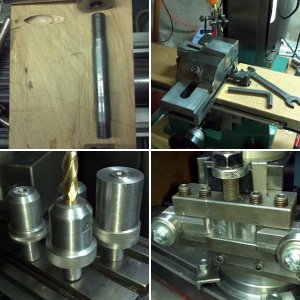

MT3 1" Slitting Saw Arbor

Feb 01

- 7,700

- 30

i started construction on a MT3 slitting saw arbor from materials in the shop. here is the slug of what i believe to be 12L14 mild steel. it was unmarked, but acted like 12L14 i have machined before. it's very nice to turn. the slug was a fraction over 1" in diameter and 7" long. i centerdrilled both ends. i turned the diameter on both ends down to .950". one for the drive dog, the other to...

Quick & Dirty Worm Wheel making

Feb 01

- 5,064

- 15

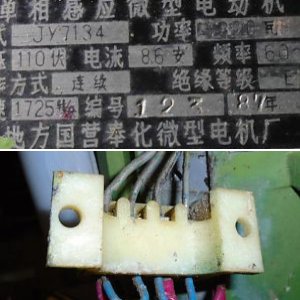

I was trying to make a substantial speed reduction to a small, but very powerful 230 Watt motor to drive a small auger. The motor specs are impressive Mabuchi Motor 12v Rs-775sf 230w 19500 rpm Model : RS-775 18V Weight : 11.9 oz Operating v : 6v - 20v Length of motor : 2.81 in Nominal v : 18v Diameter (with flux ring) : 1.85 in No Load RPM : 19500...

Shop build beast of a chop saw

Jan 27

- 4,969

- 29

I started this build couple of months ago thinking i'll finish it in a week or two so i continued writing about it in the question & answer section where i had couple of questions, but because is drag on for so long i've decided to move it in the project section.

Old gasoline generator repairs

Jan 26

- 3,659

- 21

Couple of weeks ago i bought two small generators they both "run" the smaller one needed an carb cleaning and now runs good, the Bosch uses an Tecumseh HS40 engine which has a blown head gasket, and only runs for couple of seconds and dies, the generator works so is worth repairing it.

DIY steady rest spider.

Jan 15

- 3,899

- 5

My steady rest spider turned into a bigger project because the roller shafts do not retract to utilize the diameter of the steady rest. I made new shafts from O1 tool steel with bronze tips. The spider is made from a 2.5” diameter scrap of some grade of steel, it machined nicely. I will thread for the 8 spider screws m10x1.5. First time using my rotary table, I supported the work directly...

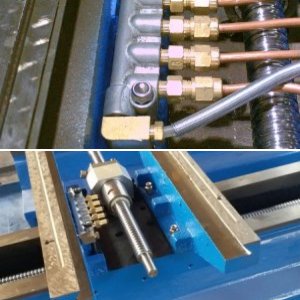

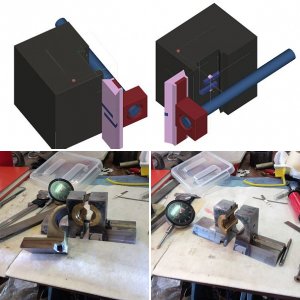

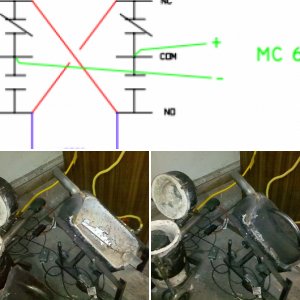

4th axis servo controlled rotary table build

Jan 09

- 7,644

- 53

Hi everyone, I am getting ready to build a 4th axis for my CNC mill. I should be getting the rotary table in the mail in about a week. I will be posting pictures as I go along  . The rotary table is one from eBay. It is of the 8" variety. I believe the brand is CME. The servo and drive is from Leadshine and is 400w. Here are a couple pictures of the servo and drive:

. The rotary table is one from eBay. It is of the 8" variety. I believe the brand is CME. The servo and drive is from Leadshine and is 400w. Here are a couple pictures of the servo and drive:

Clausing 1771 Drill Press Restoration

Dec 23

- 24,432

- 31

I picked up a Clausing variable speed drill press from a Craigslist ad. I offered the guy $200.00 and he accepted. The drill press was in decent overall condition, and had a new motor on it. I disassembled the machine and cleaned up and painted everything. Mechanically, it was in very good condition, and the only real repair work I did was to straighten a few of the handle arms. One...

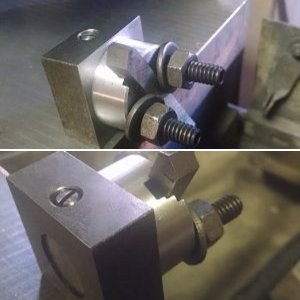

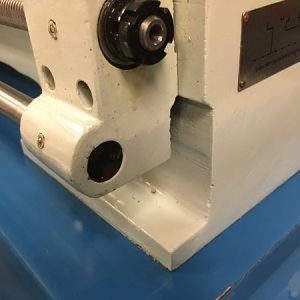

PM1340 Solid Tool Post for Dorian BXA QC

May 22

- 14,381

- 46

After some hours of use on the Best & Jacobs Full Custom Edition PM1340, I decided it was time to improve rigidity of the toolpost by implementing a solid tool mount as a substitution for the compound when I don't need the function of the compound for normal turning activity. In many ways, what I have done is a derivative of what's been done by Jbolt...

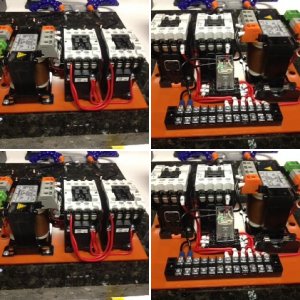

Vfd's Rpc's And 3 Phase Power At Home

May 15

- 5,833

- 8

I see a TON of questions on RPC's and VFD's on here and I figured I would type out a knowledge base for what they are and how they apply to the home shop. We as machinists work with industrial equipment at home. It's obvious if you are reading this that you know that industrial stuff is typically 3 phase and you want it to run in your home shop where there is no 3 phase power. For a long...

VN

Finally Got A Slotter Attachment

Apr 28

- 13,756

- 37

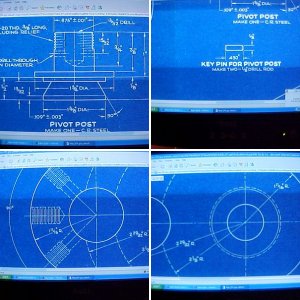

Finally picked up a slotter attachment that I have been looking for. Probably paid a bit much, but it's practically new. Stripped it and cleaned out the old gunk. Back together already, quickest rebuild yet. Missing one oil cap and the arbor, but I have a print for the arbor. All I did was clean it. Jason

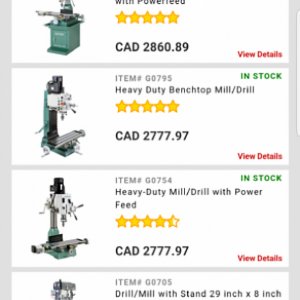

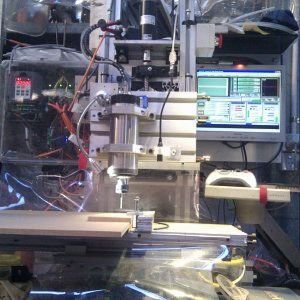

Joel Miller Cnc Milling Machine

Apr 24

- 8,073

- 5

Original at http://jmillerid.com/wordpress/category/cnc-milling-machine/ CNC mill phase 1: planning Thursday, 9 June 2011 While I have understood the basics concept of CNC machining–and have utilized it in my work–I never fully appreciated how complex a system a CNC machine is until I set about designing and building one. There are many software and hardware layers are involved in the...