-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Projects and Articles by Our Members!

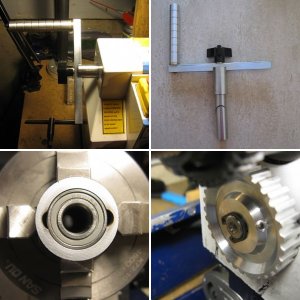

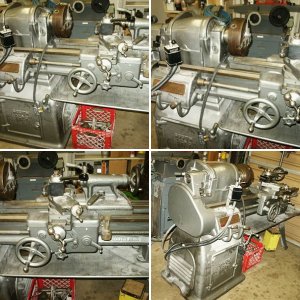

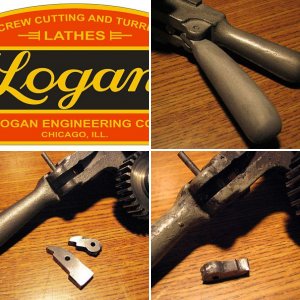

Scraping in all bearing surfaces on my Wards/Logan 10"

PIN

- 44,156

- 73

I've been working on my lathe off and on over the past several weeks or months, but I've been hesitant to start a thread documenting my progress (or lack thereof!) for fear of embarrassing myself. I'm increasingly confident that I'm going to end up with a very precise lathe rather than a very large pile of cast iron dust and tears, so I'm finally willing to share my progress. After creating...

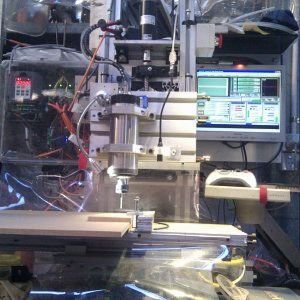

KO-Lee Cutter/Grinder Revamp

PIN

- 33,347

- 93

Perhaps you've seen this from other photos... It's a KO-Lee cutter grinder. It's a good platform and the table and all mechanisms are in excellent condition. I don't think this machine was used much in it's lifetime as there are very few signs of wear (hardly any at all really). The motor is the weak link. The bearings are going bad and vibration can be felt in the short shaft. The...

Restoring an old powered hacksaw

Jul 29

- 24,588

- 66

Figured I'd share my restoration project! I've always found these old machines quite cool and when a neighbour offered me a defective one for free, I couldn't say no!  This is the machine as I got it, it runs but won't lower the sawblade so you have to manually push it against the work piece, which becomes quite the challenge and dangerous as heck when it's moving back and forth. The...

This is the machine as I got it, it runs but won't lower the sawblade so you have to manually push it against the work piece, which becomes quite the challenge and dangerous as heck when it's moving back and forth. The...

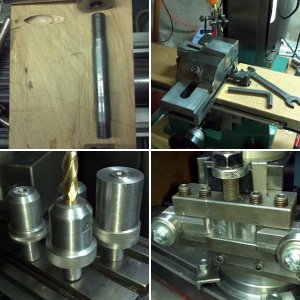

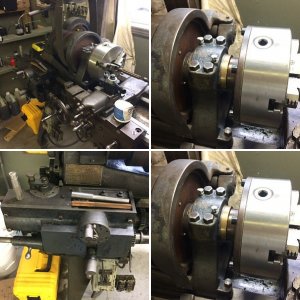

9A project completed

Sep 11

- 36,669

- 67

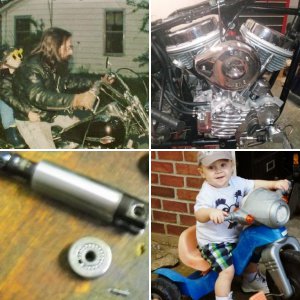

Some of you guys may remember this little crudball I acquired back in April... I had just completed the last project, the Seneca Falls #30 resto-mod,(project of the month) when this lathe found it's way to me via a friend of a friend. My friend, who is also a tool salesman, showed me a pic of this on his phone, which came from his friend, the seller, who now is a retired tool room...

Clausing 1771 Drill Press Restoration

Dec 23

- 24,435

- 31

I picked up a Clausing variable speed drill press from a Craigslist ad. I offered the guy $200.00 and he accepted. The drill press was in decent overall condition, and had a new motor on it. I disassembled the machine and cleaned up and painted everything. Mechanically, it was in very good condition, and the only real repair work I did was to straighten a few of the handle arms. One...

Odd surface plate question

Aug 25

- 1,737

- 2

So someone on craigslist is selling a couple of surface plates. They are from his father's estate and he says they are in good condition. So far so good. He has no documentation or knowledge of the manufacturer. One is a basic 12x18x3 black granite, which seems normal enough. But the other is 12x18x0.75. I've never heard of a surface plate so thin and suspect that it is unlikely to be as...

1" round rod, what can be made?

Aug 24

- 6,208

- 57

Found a 10' long section of round steel 1" in diameter. I cut off 12" length and cleaned it up a little, as it was buried in the dirt of my backyard. I was thinking maybe a hammer but it looks like most machinist hammers use a aluminum handle. What sort of stuff would you make or could be made from a 1" steel bar? With lathe only, no milling here, yet.

Cross Slide Stop for threading on my 13" South Bend?

Aug 24

- 5,836

- 33

Hello, I am struggling to return the cross slide back to the zero point in order to feed the compound in for another pass when threading. I have a single gear box (1941) 13" South Bend. It has the small dials with some backlash like all lathes. If I could dial back the cross slide to clear the threads, move the saddle back to the starting point then move in the cross slide to a positive point...

Calculating Spindle Bearing Grease Volume

Aug 20

- 2,796

- 11

Quick question / request for links... I am replacing the spindle bearings in my CNC (G0704) and I need to pack them with grease. I have an empty 7007B (https://www.vxb.com/7007B-Angular-Contact-Bearing-35x62x14-p/kit8891.htm) and an empty 7005B (https://www.vxb.com/7005B-Bearing-Angular-Contact-25x47x12-p/kit8889.htm). I have Kluber IsoFlex NBU 15 grease and a 1 ml dosing syringe. Both have...

Working With Plastics

Aug 17

- 35,510

- 23

Some people are not very familiar working with plastics. So we will continuously be adding useful info about plastics, here are few first ones we put together: Joining and Gluing ABS Painting parts with molded-in colors - a great partnership. Your Guide To ABS Drop us a note if you find this info useful. If you have more questions/topics you'd like us to cover in future posts, please...

Progress on projects

Aug 16

- 2,022

- 8

Having fun making some basic projects on the lathe. My knurler is tough to figure out, only the top wheel really digs in even when the two wheels contact the work at the same time. I suspect it's a cheap pos. But it could be me..lol Turned down a bolt for my tailstock eject function with a new drill chuck. The chuck has a hollow mt2 taper and would not push out when the drill action...

Arduino Code Help

Aug 15

- 5,000

- 40

Not sue if this is the correct forum but here goes. I'm hoping there are some Arduino guru's here. I trying to setup a feed motor that uses the state of two IR sensors to control a relay to cycle a motor on and off. The intent is to give some head room in the feed system to keep the motor from turning on/off constantly. The sensors will be spaced apart, high and low. When the space between...

Gibs adjustment

Aug 12

- 2,280

- 5

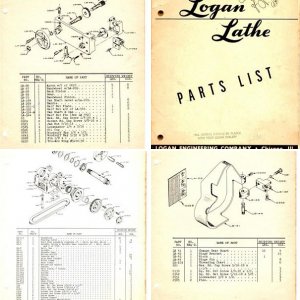

Well after making my 1st project, (aluminum container) I cleaned up all the mess and lubed stuff up. With my compound slide off I noticed a little pin with a aprox 50 degree angled face laying on my chip tray. Pulled out the parts diagram and found it's an adjusting pin for the gibs, 4 of these slide into my compound slide to adjust tighten the gibs. Oh no, I only have 2 pcs. Don't...

Suggestions for Horizontal Test Indicator

Aug 12

- 2,247

- 8

I currently have a .0005" Fowler X-Test Swiss type horizontal test indicator that I use for 95% of my setup work. I would like to pick up a new indicator with a .0001" resolution for finer work. I'm hoping to find one that is a swiss style with the swivel shank and .016" of travel (so two needles, the main one and the rev indication). The only one I can find is a $450 (edit) Interapid...

Toaster - a conversation starter

Aug 11

- 3,331

- 20

Toaster is a great conversation starter about materials usage, resource management and sustainability. We wrote a short article to start the dialogue. (https://www.plastiblocks.com/single-post/2018/08/10/Toaster---a-conversation-starter) It is so sad that majority of people who have skills don't bother repairing slightly broken, old appliances. And people who don't have skills - have no one...

Aluminum Repair With TIG Question

Aug 10

- 2,289

- 10

Hi, A co-worker asked me if I could fix his "Gold Buddy", Slues box. Please see the pics. These are bullet holes, someone pounded out the extrusion. I plan on cleaning as good as I can and placing the sheeting on a thick piece of aluminum to reduce the heat. Do a bit of pre-cleaning with the TIG torch then form a puddle and fill. Any other procedures or ideas/problems with my plan? I do have...

What kind Endmill is this?

Aug 08

- 2,991

- 15

I found in my shop 6 similar endmills in a box which I bought in 2011 and have no idea what they are for. Total length is 1.75”, 1/8” Shank, 1/8” OD and 2 are 2 flute, 2 single flute and 2 V shape ends. What the purpose of the orange sleeve at the end of the shank? If I will use them to trim aluminum what will be the recommended RPM?

How to Machine This Part

Aug 04

- 2,594

- 13

A friend at work asked if I could machine a new handle for this super old clamp I think it is. I know he's got an old manual drill press that needs fixing but this looks like a handle from a clamp. I think the end on the screw can be pressed out but not sure how to get the handle off. Thinking this must be cast iron. He wants it remade in cast iron which I'm not to excited about but said I'd...

DRO but Which One?

Aug 03

- 3,302

- 21

I know this horse has been beat to death.The more I read and watch Utubes my headache getting worse,I have read post back several yrs ago and different forums to kinda present day and time.Guys I am just weekend wannabe machinist type person just doing this for fun so nothing serious but I want it to be spot on and trouble free(possible) I know that comes at a cost.Guys I can't come close to...

Unique Chess Set

Aug 02

- 32,058

- 12

Just when you thought "what else can be done with the chess set", a new idea comes along... This is what a chess set using Plasti-Block™ ABS dual color rods could look like. Other color combinations can also be fun! Let us know what else would you like to see modeled using this product. We are looking forward to hear your ideas. Plasti-Block™ Team

What to practice on lathe

Aug 02

- 9,610

- 82

Hello everyone, I was thinking you all could list some practice cuts or things to start off practicing on the lathe. I have only done face cuts so far and starting to think I should practice steps, curves, shoulders, etc Really no idea what to practice first or what will build up good lathe skills for when I actually turn a project. I have heard some people practice making bullets...

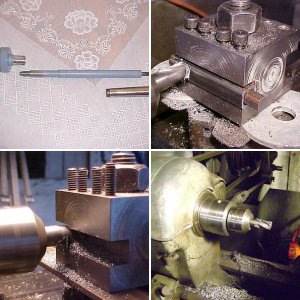

1st chips, no blood

Jul 31

- 3,257

- 24

Finally did it, took .030 " off the end of a 1" rnd aluminum bar stock. 1st cut ever!!! So excited to finally make a pass on the new metal lathe!!

Couldn't contain myself, lowered the tool post slightly and took .005 off. I am loving it, made great swarth, nice long pcs and some 1-2" spiral pcs..haha I know my technique is bad as I have no practice, I could tell I...

Couldn't contain myself, lowered the tool post slightly and took .005 off. I am loving it, made great swarth, nice long pcs and some 1-2" spiral pcs..haha I know my technique is bad as I have no practice, I could tell I...

Couldn't contain myself, lowered the tool post slightly and took .005 off. I am loving it, made great swarth, nice long pcs and some 1-2" spiral pcs..haha I know my technique is bad as I have no practice, I could tell I...

Couldn't contain myself, lowered the tool post slightly and took .005 off. I am loving it, made great swarth, nice long pcs and some 1-2" spiral pcs..haha I know my technique is bad as I have no practice, I could tell I...My Power Feed Broke

Jul 30

- 1,526

- 6

Just stopped working. Suddenly I started hearing a loud tick. Stopped the machine to investigate. There is a collar that the feed rod runs through. I'm pretty sure that normally this collar (thinking it might clamp down on the rod) is stationary not rotating like it is now. Ideas? Thanks in advance.

Machine Grade Rods & Blocks

Jul 23

- 3,112

- 5

Our plastic raw material products will enable small, medium and large companies, including manual & CNC shops, makers, designers, model builders, furniture manufacturers, cabinet makers, hobbyists, prototyping bureaus and more. Our machine grade blocks and rods are available in small quantities, in different colors and at very affordable prices that can boost creativity and will help your...

Trying to Weld Unknown Aluminum Scrap-No Success!

Jul 21

- 2,237

- 10

Hi, I am trying to get to know my Miller Diversion 180 with regard to Aluminum. I picked up some bent scraps at the local source. All I know is it is aluminum. I have read that some aluminum alloys can't be welded, I guess I found one. I have had success welding aluminum so I am not a total newb. but close. I set the dials to "Aluminum", 1/8" = 105 amps AC. The cleaning action is normal, the...

First real part...parting woes!

Jul 11

- 3,540

- 20

Been awhile since posting so I thought Id share the first actual part I made on a lathe that actually will serve a purpose...drawbar spacer for the Atlas 618. Everything went well until I decided to try to part off, way too much chatter. I have the qctp from LMS and the blade type cutoff tool that fit in the tool holder. I will read up on the parting issue as I know there is much info here...

Newb quick change tool post/tooling suggestions

Jul 09

- 15,268

- 58

Good evening fellas. I am picking up my G0602z at the UPS hub in the next few days (renting a trailer so I can drive it directly into my garage) anyway, I was looking at QCP as I won't have the patience for the stock one. Any suggestions? I realize it is a budget lathe so of course I'm not looking at a $1000 setup, but if it doesn't work well and isn't good at being....well, a quick change...

Tramming my Mill

Jul 08

- 2,647

- 9

Does anyone see a problem with tramming like this. I like to use the vise as that is where my work is held. The parallels are 4-way Anton .0003" accurate on height, width and straightness.

Indicol 178 and Starrett Last Word 711

Jul 07

- 2,921

- 7

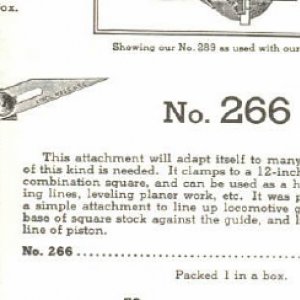

I probably should have done my homework before buying these two items. Can anyone here tell me what attachment I need that will make these two compatible? The 711 came with a body clamp for a 1/4" diameter shaft and the 178 is rigged for an indicator with a dove tail.

Tapping for 10-32

Jul 05

- 14,421

- 31

I do a fair amount of 10-32 tapping on aluminum and it’s a hard going. I use a 5/32” drill which came as a set with the tap but I wonder if another drill size may do the job faster As an example I also tap a lot of M5 and I was using #19 drill which was also a hard going but I discover from a thread in another forum that an 11/64’ drill is much better and in it is. Is the 5/32” drill the...

SB 16X60

Jul 01

- 3,060

- 21

That machinetoolcollectionitius disease struck again. I picked up a 16" x 60" SB today. Came with a 12" 4 jaw, complete 5c collet set, with a nice tray, that someone set up to mount at the tail stock, or head stock. A well abused 8" 3 jaw (yes, thats a crack above the 5 &6). a spare 8" backing plate, the wrenches for the saddle and tail stock locks, and a 4 way tool post. And most of a...

Estate Sale scores. And need to identify the Ames Indicator.

Jun 30

- 3,337

- 14

Scored some miscellanea this weekend. Can't figure out what the Ames indicator setup was used on. Only markings are the typical 'Pat. App'd' The brass Transit(?) item is rather neat. The logo on the pocket tape is cool I think. ...... ...... ...

Table-Top or Toolpost Shaper

Jun 17

- 8,922

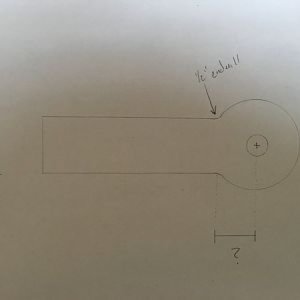

- 33

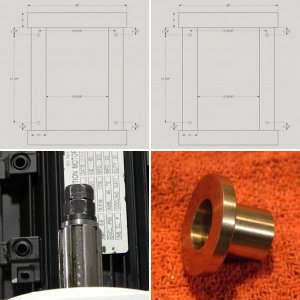

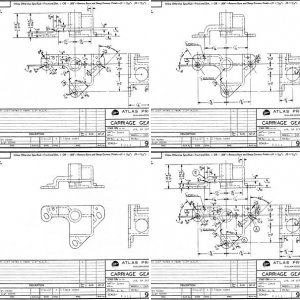

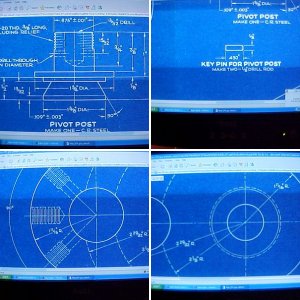

Here's a "working" concept of a small shaper. The design goal is for it to work in the lathe via a toolholder in the toolpost or, on a small table-top fixture. The main use will be for cutting fairly small keyways in pulleys or gear bores. I'm also using this project to learn Fusion 360 after many years of Alibre CAD. The design is based on the classic Whitworth "Quick Return"...

Upgrade Vintage Tool Chest with Ball Bearing Slides Using Plywood?? by Bill70j

Jun 09

- 28,196

- 9

I have a 70's vintage Craftsman tool chest, a gift from my wife way back when. It has old metal-on-metal friction drawer slides that have never worked. It' a chore to get the drawers open. Upgrading to ball bearing slides seemed easy enough. But how to mount the new slides without welding? I'm no good at welding sheet metal, plus I didn't want to ruin the finish. The solution kept coming...

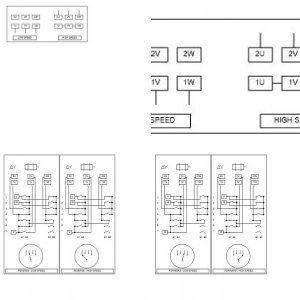

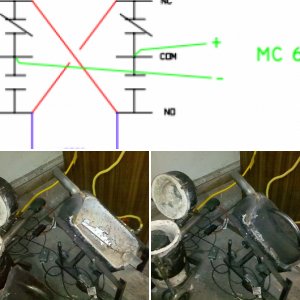

Matt offered me a 3ph motor Now wiring the VFD?

Jun 07

- 5,931

- 26

I have desided to go with a new 3ph upgrade from Matt. The caps didn’t work so mat thinks the centrifical switch is dead. Now while I was researching 3ph conversion, I saw a post on wiring the PM932 forword, stop reverse switch, and E-stop so as not to release the smoke out of the new parts, being the dummy I am, I didn’t mark it for reference. Now I can’t seem to find it again. Most likely...

Dayton 6Y945 2x42 belt sander mods for HSS tool grinding..

May 28

- 23,700

- 30

After falling down the mini lathe rabbit hole I discovered yet another one when the enablers on this site ganged up on me. After being amazed by how well the tool worked that @ttabbal ground and sent to me I set out to be able to grind my own. Then came a 1000 PM's back and forth with @mikey on what I needed for a sander and exactly how to go about the actual grinding. Once I got @mikey 's...

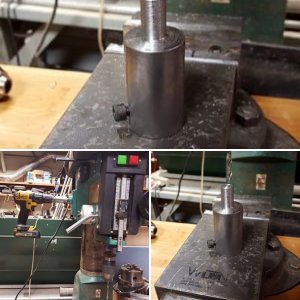

Metal Stamp Fixture

May 16

- 2,381

- 8

I have in the past tried to use my import metal stamp kit with little or no success. The numbers never seem to be in a straight line with some up and some down. Trying to keep them positioned correctly is almost impossible and the spacing between them is never right. some are stamped too hard and others are not hard enough. So I decided I would have a go at making a holder that would rigidly...

Gilbert Erector set part number CQ slotted coupling

May 12

- 3,263

- 6

Spring time in Michigan so time to get back into the shop to reproduce more Erector set parts. The part here is Erector part# CQ slotted coupling. It’s a 5/16” diameter piece of brass 5/8” long. It has 6-32 and 8-32 tapped holes and a slot for attaching a flat strip to the cylindrical bushing. I’ll start with the obligatory Erector history lesson . . . The CQ was introduced in 1924 and...

Spotlight Clock

May 05

- 2,136

- 8

I really like these clock movements as they are self contained, good quality, and not too expensive. I used one in my Grandfather clock I made last month. https://www.hobby-machinist.com/threads/grandfather-clock-shrunk.69286/#post-580047 They come in several different styles and sizes. I am using the 3.5 inch model here. I have a couple of automotive a/c dryers from the...

Power Z Conversion For PM45

May 05

- 5,810

- 25

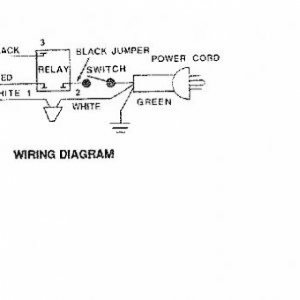

I have an early model PM 45 mill that has the manual hand crank for Z elevation. Since I just reorganized my shop and a toolbox is placed nearby, I'm going to attempt to convert it to powered elevation using a heavy duty gear motor that I've had for a long while. I'm not 100% sure this will work to my satisfaction. The odds are maybe 70%... We'll see. I'll outline the design...

Tool Grinding Experiment

Apr 29

- 2,981

- 10

Being motivated by Mikey's great instruction on tool grinding, I dove in today and seems I was reasonably successful. Success (I think?) grinding a turning (square) tool. I'm sure it would be easier with the models on hand, but wanted to try it just based on Mike's pictures and descriptions. I think I'm close (it seemed to work very well in brass, just ok on 303 stainless) I installed the...

Flywheel for Grasshopper Engine

Apr 26

- 2,802

- 6

Dear All, It has been too long since I visited! So, I have decided to post a POTD. I am just starting to build Elmer's Grasshopper beam steam engine model. The first task I tried was the flywheel. I changed the plans a bit, as I decided to go with a 3.5" flywheel instead of the 3" flywheel the drawings call for. More mass should make for a better grass...hopper. I had previously made the...

GPS Mount

Apr 23

- 1,641

- 2

Just a small project I've been tinkering with for a couple of days... its an aluminum mount to hang a GPS in my truck. I hate the suction cup mounts and don't like any of the other available mounts any better, so I kinda came up with my own design. And the (almost) finished product... I still have to finish mounting it, but I think its going to work pretty well. -Bear

New Power Finger File.

Apr 23

- 1,987

- 2

I wanted to use aluminum for this project, 10mm thick would have done the job but I had no idea where to souurce that size sheet from; however, I did have some sheets of 25 mm Delrin so I thought I'd have a bit of a play with that medium. Delrin turns nicely giving a nice finish, but when grinding and filing the finish is quite rough. I expect some more work in this area to neaten the project...

Dividing head,what a great tool to have

Apr 18

- 3,287

- 15

I love my new vertex bs-0 dividing head. It opened up a whole new world of possibilities for me. I know this has probably been posted a gazillion times,but I feel like sharing. Today I made myself a dovetail cutter using two TCMT 16T308 MP NC 3225 inserts with a positive rake and 7degree relief angle. I did not take enough pics for this post.....was enjoying myself too much. What you don't...

Bearing replacement on steering gear shaft.....

Apr 15

- 1,866

- 3

A few years ago I helped a friend that was converting a Toyota Echo from gas to electric. I made a steel plate for the transmission housing that mounted the big electric motor, and a coupler to connect the two shafts. During the conversion he changed from a hydraulic power steering to an electric unit, which was hard to find. Recently, he discovered that the seals on the electric power...

Big bench grinder build.

Apr 11

- 1,498

- 0

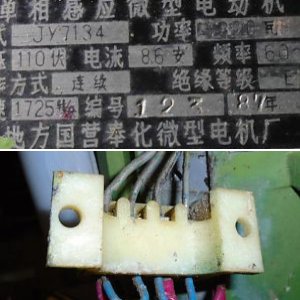

I have an two grinder sharpening station in my machine shop but i don't have a bench grinder in my big garage. looked around and the bigger 200-250 mm stone size grinders are pricey so i thought why not build one the size i need and of course make it more powerful. After considering couple of belt driven designs decided to make it direct drive but to use a 2Kw (2 3/4 Hp) 2800 rpm motor out of...

Made a Reloading Block Today

Apr 08

- 1,957

- 2

I've been wanting to do this for a long time. Today was the day. It is 4"X8" and holds standard and magnum cases. I'm happy with the way it turned out.

A Nice Gear Tutorial #1

Apr 07

- 39,313

- 16

I'm going to make some gears soon and came across this while brushing-up and refreshing my memory. Of course, the Machinist's Handbook has it all but, this is a very nicely authored and to-the-point tutorial. This is based on Diametral Pitch and not the Module method. I have some other guides based on Module method but need to check the copyright information. Enjoy... Ray

QCTP Tool Holder Rack

Apr 04

- 4,067

- 4

I have slowly been adding to my collection of AXA style tool holders and it has become necessary to better organize them. The small size of my work area precluded a wall mounted storage unit. I decided that a rack mounted at the top of the backsplash wouldn't be too much in the way of machining and tools would be readily accessible. The plan was to make vertical hangers for the tool holders...

One MOW Flycutter

Mar 27

- 3,629

- 19

I started this little project before cold weather settled into the south, north central Florida. Cut a piece of 1 inch thick cold roll to get a disc a little larger than 5 inches. Drilled and bored the center to .750 -.05 for shrinkage. Heated the disc up to a nice red-ish tone and shut down the flame. Dropping the shaft that was in a cut frozen in the freezer over night. After sticking it...

Large Steady Rest

Mar 20

- 3,911

- 13

The steady rest that came with my PM-1440GT lathe only opens up to a little over 2". With shorter fingers I can get up to 3-1/4". I want to be able to work on larger diameter tubing so a larger steady rest is in order. The max swing over the cross slide is 8-3/4". My current design will allow up to 8". I looked at various DIY steady rests, some over the top and other pretty awful. I don't...

Cartridge Calibration Press

Mar 17

- 3,940

- 23

Hello, My entire cartridge gauge design where you go from one end of Die to another, so the calibration is complete. The machine has some oxidized parts and stems with hard chrome; The Dies were bought from bought. Hope you like it !

PM30 Milling Machine Stand

Mar 11

- 4,645

- 14

Building a bench for my soon to arrive Precision Matthews PM30MV. Planning to roll an old craftsmen tool chest underneath. Not totally sure on the bench surface yet. A side note, this is a bad time to purchase steel!! $$$ A sketch: Steel is cut, cleaned and de-burred: Tacking together the front and back sections: Now I need to figure out how to attach the cross members while keeping...

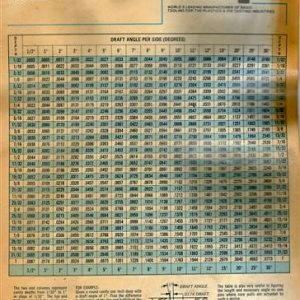

Just a few things I've picked up over my 2-year Machining Studies

Mar 06

- 2,676

- 9

Creating this thread to share some manual mill/CNC stuff I've picked up so far at work/school. Some nice little charts here if you want to print them out. The center drill sizes are basically what I program the controls for depth for each size, because it's tricky finding one that works I've jotted ones that do here. Also the SFM is a bit different, but if you look at the bottom guide it will...

Spindle Stop

Mar 04

- 2,250

- 6

My version of a spindle stop for my PM-1440GT lathe with 2" spindle bore. I have been using this stop for a while. Made from Delrin, a 3/* aluminum rod and 3/16" & 1/4" drill rod at the ends. It is held in place by one of the outboard spider setscrews and adjusted with a 1/4-20 setscrew. Something I made up quickly for a job. Works okay but a bit of a pain to quickly install and adjust...

Air power file conversion to 12 volt.

Feb 26

- 1,965

- 6

I bought an air belt grinder a while back which proved a little too air hungry for my compressor, so, rather than buy a bigger compressor I converted it to run off 12 volts. The motor came from ebay as a 12 volt cordless drill motor spinning at 5000 rpm. I removed the air motor and as luck had it the 12 volt motor fitted perfectly in the grinder housing. I also turned up a 12 mm bush with a...

Squareness comparator/surface guage

Feb 21

- 6,173

- 23

Started this a while ago, keeps getting out on the back burner due to shop problems and break downs. Still working on my lathe DC drive system that failed... It's based on Stefan Gotteswinter's project. Did a bunch more mill work last night on the top slide piece. And my progress so far. To use as a surface guage, I can just spin the top slide around to the back and extend the DTI off the...

10 cylinder Crankshaft

Feb 20

- 3,425

- 7

I’ve been wanting to make an interesting form that used eccentric turning. I wanted to make it as long as feasible on my hobby machines and I would display it vertically. I did some research on cams and got to thinking that they are too solid of a piece. That led me to crankshafts that were much more “airy”, and certainly more difficult to make. I remembered seeing a thread once on one of...

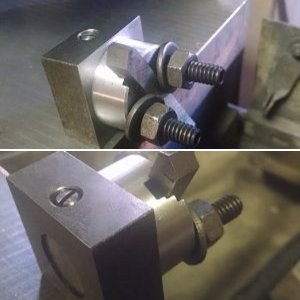

Ellis Saw Vise Clamp

Feb 12

- 3,487

- 7

My Ellis band saw has a quick acting vise for holding the stock in place while cutting. The vise can not be located real close to the blade and can cause a clamping issue when trying to cut really short pieces even shorter. So, here is my solution. I made an adjustable clamp. Seems to work pretty well. And yeah I know, it still needs some paint.

Indexing plate!

Feb 12

- 4,542

- 20

-20F this morning again........... This morning's project was to finish up on an indexing plate that I had started the day before. Not that I really needed a project but wanted to test out the bolt circle feature on my Mitutoyo digital readout. As luck would have it I had a steel disc or the right thickness but a little larger in diameter than the original indexing plates. I picked...

This morning's project was to finish up on an indexing plate that I had started the day before. Not that I really needed a project but wanted to test out the bolt circle feature on my Mitutoyo digital readout. As luck would have it I had a steel disc or the right thickness but a little larger in diameter than the original indexing plates. I picked...

DIY chamber headspace gauge.

Feb 11

- 3,568

- 3

I made a simple headspace gauge for installing a 45 conversion barrel to a Mauser action. Final length was done by stoning a few tenths off.